What is Fuel Tank Zinc Plating?

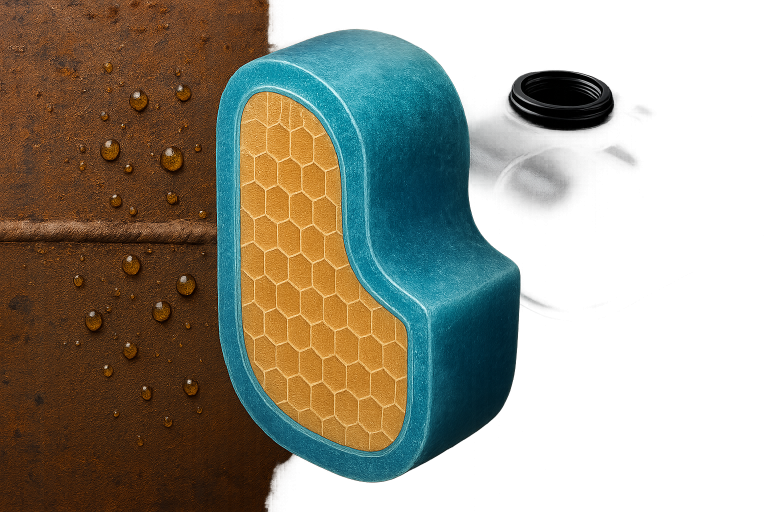

Zinc plating is a process in which a thin layer of zinc is electroplated onto a metal surface in order to protect it from corrosion and wear. Zinc is a highly reactive metal that is resistant to corrosion, making it an effective coating for metal surfaces that are exposed to harsh conditions.

Fuel tanks can be zinc plated in order to improve their corrosion resistance and durability. Zinc plating can help to protect the fuel tank from the harsh conditions that it is subjected to, including heat, moisture, and chemical exposure. It can also provide a decorative finish for the fuel tank.

To zinc plate a fuel tank, the tank is first thoroughly cleaned and prepared. It is then placed in a zinc plating bath, where an electrical current is used to deposit a thin layer of zinc onto the surface of the tank. The tank is then removed from the bath and rinsed to remove any excess zinc.

Zinc plating is a specialized process that requires specialized equipment and expertise. It is typically performed by a professional plating company or a metal finishing shop.

The Cost of Fuel Tank Zinc Plating

The cost of zinc plating a fuel tank will depend on a variety of factors, including the size and shape of the fuel tank, the thickness of the zinc coating, and the location of the plating shop. Here are a few factors that can affect the cost of zinc plating a fuel tank:

- Size and shape of the fuel tank: Larger or more complex fuel tanks may require more time and materials to plate, which can increase the cost.

- The thickness of the zinc coating: A thicker coating may provide better protection for the fuel tank, but it will also be more expensive.

- Location of the plating shop: The cost of zinc plating may vary depending on the location of the plating shop and the local cost of labor and materials.

It is difficult to provide a specific cost for zinc plating a fuel tank without more information about the specific tank and the desired thickness of the coating. To get an accurate estimate for the cost of zinc plating a fuel tank, it is recommended to contact a professional plating company or metal finishing shop and provide them with the details of your project. They should be able to provide you with a quote based on your specific needs.

Issues You Might Face With Fuel Tank Zinc Plating

While zinc plating can be effective in protecting metal surfaces, it can also have a few potential problems. Here are a few common problems that can occur with zinc plating:

- Peeling or flaking: If the zinc coating is not properly adhered to the metal surface, it may peel or flake off over time. This can be caused by a variety of factors, including improper surface preparation, poor quality zinc, or inadequate cleaning or drying of the metal surface.

- Corrosion under the zinc coating: If the zinc coating is damaged or becomes porous, it can allow moisture and other corrosive substances to reach the metal surface beneath, causing corrosion.

- Porosity: If the zinc coating is not applied evenly or is too thick, it may be porous, which can reduce its effectiveness as a protective coating.

- Electrolytic corrosion: If the zinc coating is applied to a metal with different electrochemical potential, it can cause electrolytic corrosion, in which the zinc coating acts as an anode and the metal beneath it acts as a cathode, causing the zinc to corrode and the metal to be protected.

To minimize the risk of these problems, it is important to use high-quality zinc and to follow proper plating techniques, including thorough surface preparation and proper application and drying of the zinc coating. It is also important to regularly inspect and maintain the zinc coating to ensure that it is in good condition.