Turning Waste into Watts: Record-Breaking Solar Cell Paves the Way for a Greener Future

Researchers at Nanyang Technological University (NTU) in Singapore have recently set a new benchmark in solar energy technology with a waste-based hybrid organic-inorganic perovskite solar cell (HPSC) that achieved an energy efficiency of 21.39%. Even more impressively, the cell retained 90% of its efficiency after 1,100 hours of operation.

This breakthrough, achieved by incorporating a biomass-derived polymer from agricultural waste, offers a promising pathway for producing more efficient and environmentally sustainable solar cells. In this article, we delve into the details of this innovation, explaining the technology, its significance, and the challenges it addresses.

The Science Behind Perovskite Solar Cells

Perovskite solar cells have attracted attention for their potential to exceed the performance of traditional silicon-based cells. These cells use a specific crystal structure—known as the perovskite structure—to create a material that is highly effective at absorbing sunlight and converting it into electricity. In laboratory settings, perovskite cells have reached efficiencies of over 34%, yet translating these high efficiencies into commercially viable products has proven challenging due to issues with stability and the reliance on petroleum-based components.

The Role of Biomass-Derived Polymers

A key innovation in NTU’s record-setting solar cell is the replacement of petroleum-derived polymers with a polymer extracted from agricultural waste. Traditionally, the photoactive layer in perovskite solar cells uses conjugated polymers that are derived from petroleum. These conventional polymers pose two major issues:

- Sustainability: Petroleum-based polymers are non-renewable and contribute to environmental pollution.

- Fabrication Complexity: Their solubility characteristics can complicate the manufacturing process, as they often require the use of additional, petroleum-based solvents, which can limit compatibility with other materials.

The researchers at NTU addressed these problems by using a furan-based polymer, known as FP1-H, derived from agricultural waste. Furan polymers have a unique chemical structure that includes aromatic compounds. These compounds improve the solubility of the polymer in common precursor solvents, making the fabrication process simpler and more environmentally friendly.

How FP1-H Enhances Efficiency and Stability

The integration of FP1-H into the perovskite solar cell stack has several critical benefits:

- Improved Film Crystallization: The furan-based polymer tends to accumulate at the grain boundaries within the perovskite layer. This accumulation leads to better film crystallization, meaning that the microscopic crystals in the solar cell are more orderly and aligned. Better crystallization enhances the pathways for electrical charge carriers (electrons and holes), reducing losses and improving overall efficiency.

- Enhanced Charge Transport: With fewer defects and improved crystallization, the movement of charge carriers through the cell is more efficient. This leads to a higher short-circuit current density, which is a measure of the current produced per unit area under illumination.

- Long-Term Stability: The cell’s ability to retain 90% of its initial efficiency after 1,100 hours is a significant improvement over cells that do not incorporate the furan-based polymer, which typically retain only about 52% efficiency over the same period. Stability is crucial for the practical deployment of solar cells, as it determines how long a cell can effectively convert sunlight into electricity before its performance degrades.

The Fabrication Process: Automated and Scalable

A notable aspect of this breakthrough is how the incorporation of FP1-H simplifies the fabrication process. The process involves:

- Material Deposition: The furan-based polymer is dissolved in a solvent and then deposited onto the glass substrate along with other perovskite precursors.

- Film Formation: The deposition is followed by a controlled crystallization process, where the polymer accumulates at grain boundaries and helps the perovskite film to form a more uniform, crystalline structure.

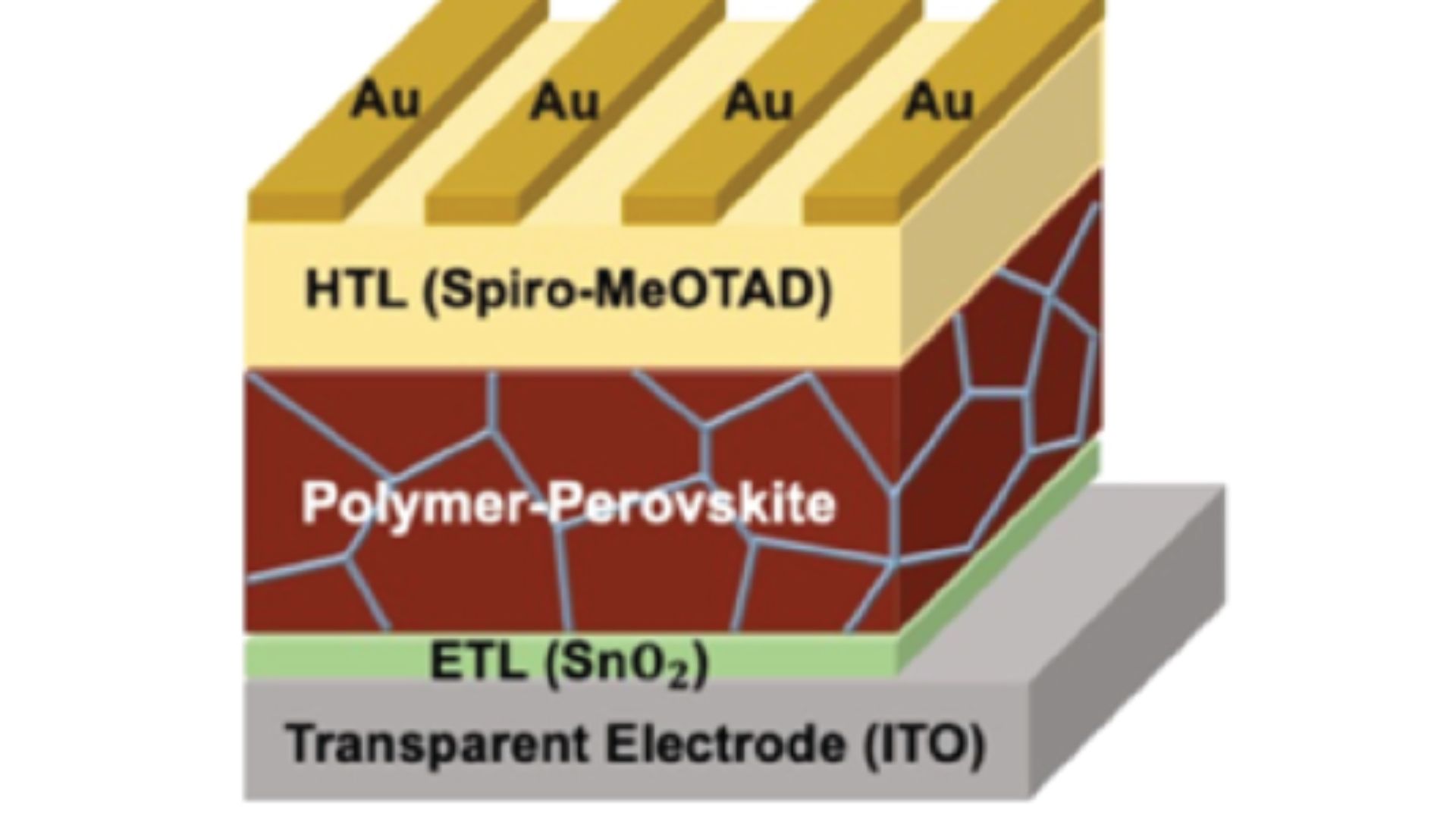

- Integration into Device Stack: The complete device stack, which includes additional layers such as charge transport layers and electrode contacts, is assembled in a way that integrates FP1-H directly into the device. This direct precursor integration method reduces the number of steps and solvents required, making the overall production process more streamlined and potentially more cost-effective.

Addressing the Challenges of Scaling Up

Despite the promising laboratory results, several challenges remain in scaling this technology for commercial use:

- Material Yield: One of the hurdles is the relatively lower yield of furan compared to petroleum-derived polymers. The research team is actively developing new synthesis approaches to increase the availability and consistency of the furan-based polymer.

- Long-Term Durability: While laboratory tests have shown excellent short-term stability, the long-term performance of these solar cells under varied environmental conditions will need to be validated through further testing.

- Manufacturing Integration: The new fabrication process must be integrated into existing manufacturing lines without significant disruptions or cost increases. This requires collaboration with industry partners to adapt current production methods to the new technology.

Broader Implications for Renewable Energy

The success of this waste-based solar cell has far-reaching implications for the renewable energy sector:

- Environmental Impact: By replacing non-renewable, petroleum-based materials with a polymer derived from agricultural waste, the technology supports the principles of a circular economy. This not only reduces waste but also lowers the environmental footprint of solar cell production.

- Efficiency Improvements: With an efficiency of 21.39%, this solar cell represents a substantial improvement over conventional cells, which typically convert only about 20-22% of incident sunlight into electricity. Even small percentage increases in efficiency can lead to significant gains in energy output at scale.

- Commercial Viability: Enhanced efficiency coupled with improved stability makes these solar cells more attractive for commercial deployment. They offer a pathway to more reliable and cost-effective solar energy solutions, which are essential for meeting global energy demands sustainably.

Conclusion

The development of a waste-based hybrid perovskite solar cell with a record efficiency of 21.39% and remarkable stability marks an exciting milestone in the evolution of solar technology. By leveraging a furan-based polymer derived from agricultural waste, researchers have not only boosted the performance of the solar cell but also simplified its fabrication process and reduced its environmental impact. While challenges remain in scaling the technology and ensuring long-term durability, this breakthrough offers a glimpse into a future where waste materials are transformed into powerful energy solutions. As further research and development continue, innovations like this could play a pivotal role in creating a more sustainable and resilient renewable energy landscape.