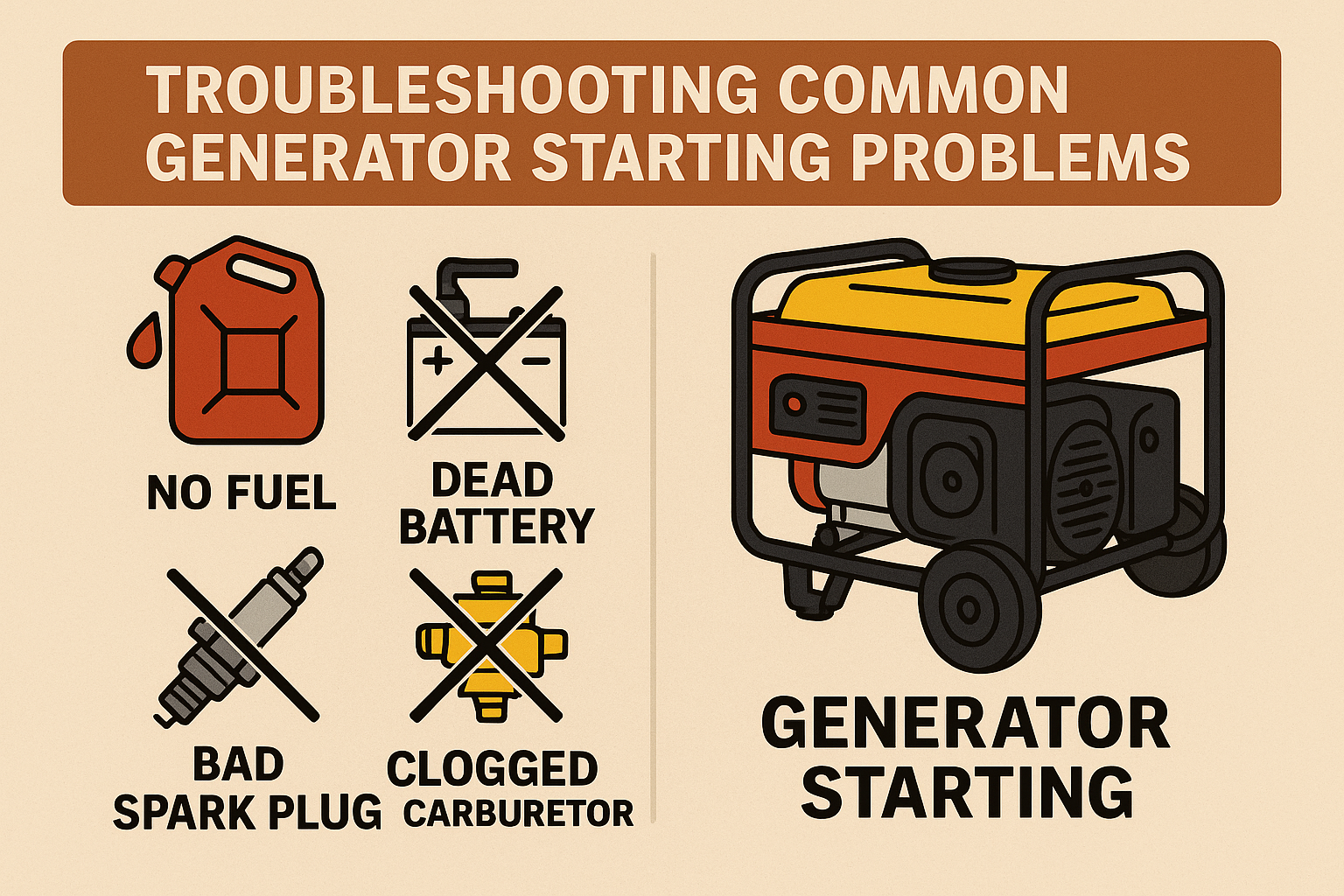

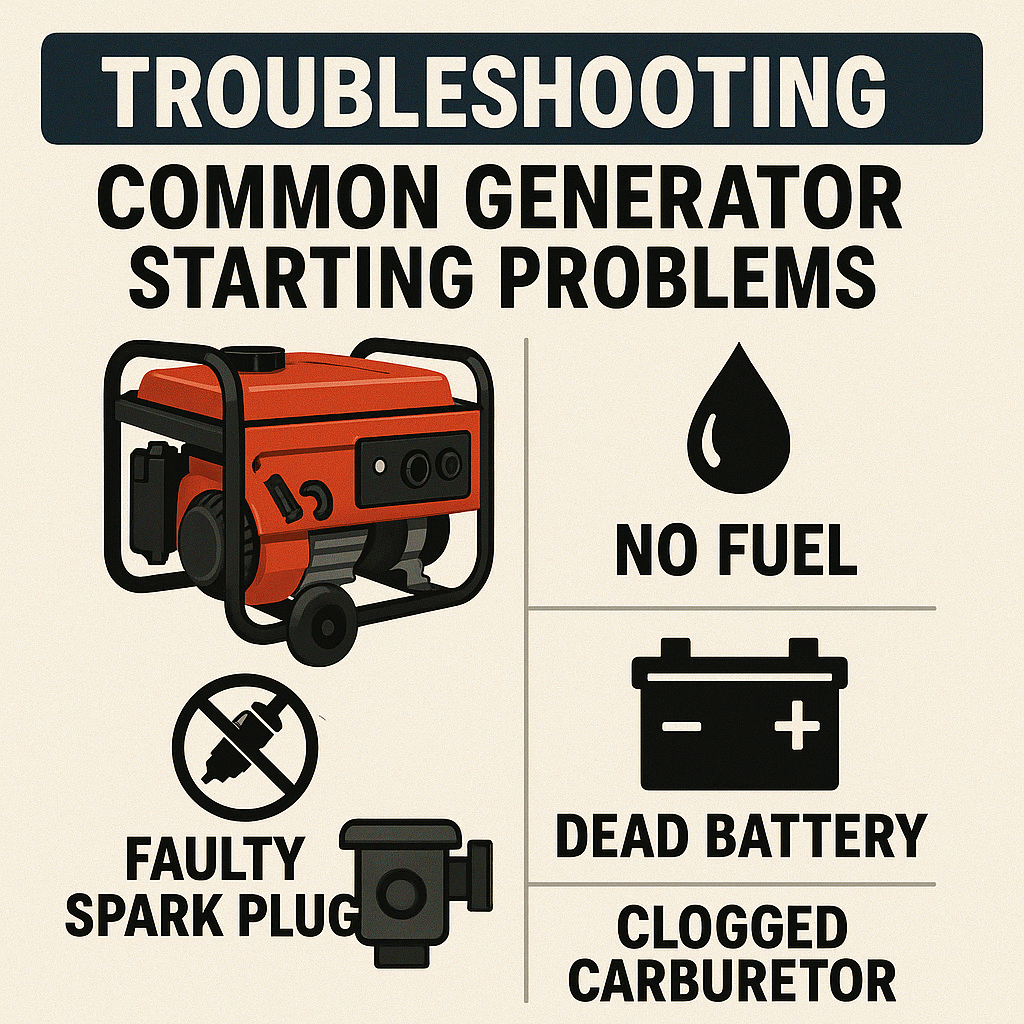

Troubleshooting Common Generator Starting Problems

When the lights go out, your generator is supposed to be the hero – not the villain. But what happens when it refuses to start, leaving you in the dark (literally and figuratively)? Generator starting issues are frustratingly common, but they’re often easy to fix if you know where to look. In this comprehensive guide, we’ll walk you through the most frequent causes of generator startup failures and provide actionable solutions to get your power back on track.

Why Generators Fail to Start: The Top Culprits

Generators are robust machines, but they’re not immune to wear, environmental factors, or simple neglect. Here’s a breakdown of the usual suspects when your generator won’t start:

- Fuel System Problems

- Ignition Failures

- Battery or Electrical Issues

- Mechanical Breakdowns

- Environmental Factors

Let’s dive into each category with troubleshooting tips, real-world examples, and pro advice.

1. Fuel System Issues: The #1 Cause of Startup Failure

Symptoms:

- Engine cranks but doesn’t ignite.

- Starts briefly, then stalls.

- Strong gasoline smell or visible leaks.

Common Fixes:

A. Stale Fuel

- Why It Happens: Gasoline degrades in as little as 30 days, forming varnish that clogs the carburetor.

- Solution:

- Drain the old fuel (use a siphon pump for portables).

- Refill with fresh gasoline and add a stabilizer like STA-BIL.

- For ethanol-blended gas, consider a fuel additive to counteract moisture.

B. Clogged Carburetor

- Why It Happens: Stale fuel leaves gummy residue in the carburetor jets.

- Solution:

- Remove the carburetor and clean it with a carb cleaner spray.

- Use a thin wire to clear blocked jets.

- Pro Tip: Install a fuel shutoff valve on portable units. Turn it off and let the generator run until the carburetor is empty before storage.

C. Blocked Fuel Filter or Line

- Why It Happens: Dirt or debris restricts fuel flow.

- Solution:

- Replace the fuel filter (a $10 part).

- Blow compressed air through the fuel line to clear obstructions.

Real-Life Example: A homeowner stored their generator for six months without stabilizing the fuel. The carburetor became so clogged that it required a professional cleaning. Cost: $150. Lesson: Always stabilize fuel!

2. Ignition Problems: No Spark, No Start

Symptoms:

- No sound of ignition (just cranking).

- Engine sputters but won’t fully turn over.

Common Fixes:

A. Faulty Spark Plug

- Why It Happens: Carbon buildup, incorrect gap, or cracked porcelain.

- Solution:

- Remove the spark plug and inspect for damage.

- Clean deposits with a wire brush or replace the plug (5–5–15).

- Adjust the gap using a feeler gauge (check your manual for specs).

B. Ignition Coil Failure

- Why It Happens: Coils degrade over time, leading to weak or no spark.

- Solution:

- Test the coil with a multimeter. Resistance should match the manual’s specs.

- Replace the coil if readings are out of range (30–30–80).

C. Kill Switch Malfunction

- Why It Happens: The switch is accidentally left in the “Off” position.

- Solution:

- Check the switch (often near the throttle) and toggle to “On.”

Pro Tip: Spray a small amount of starting fluid into the air intake. If the engine fires briefly, the issue is fuel-related. If not, focus on the spark plug or ignition coil.

3. Battery & Electrical Failures (Electric-Start Models)

Symptoms:

- No response when turning the key.

- Clicking noise but no cranking.

Common Fixes:

A. Dead or Corroded Battery

- Why It Happens: Lack of use, old age, or corroded terminals.

- Solution:

- Clean terminals with a baking soda/water mix and a wire brush.

- Recharge the battery with a trickle charger.

- Replace batteries every 3–5 years, even if they “seem” okay.

B. Faulty Starter Motor

- Why It Happens: Worn brushes or internal damage.

- Solution:

- Bypass the starter with jumper cables (connect directly to the battery). If it spins, the starter is fine.

- Replace the starter motor if unresponsive (100–100–200).

C. Loose or Corroded Wiring

- Why It Happens: Vibrations shake connections loose.

- Solution:

- Tighten all wiring connections, including the ground wire.

- Use dielectric grease on terminals to prevent future corrosion.

Real-Life Example: A family’s standby generator failed during a storm. The culprit? A corroded battery terminal. A 10-minute cleanup job saved them from a $300 service call.

4. Mechanical Failures: When Parts Wear Out

Symptoms:

- Engine seizes or makes grinding noises.

- Pull cord recoil doesn’t retract.

Common Fixes:

A. Low Oil Shutdown

- Why It Happens: Many generators have an automatic shutoff to protect the engine.

- Solution:

- Check the oil level with the dipstick and refill to the recommended mark.

- Use the manufacturer’s recommended oil type (e.g., 10W-30).

B. Seized Engine

- Why It Happens: Long-term storage without oil or lubrication.

- Solution:

- Remove the spark plug and pour a teaspoon of oil into the cylinder.

- Let it sit for 24 hours, then gently rock the flywheel to loosen the piston.

- If stuck, consult a professional—forcing it can cause irreversible damage.

C. Broken Recoil Starter

- Why It Happens: The pull cord snaps or the recoil spring breaks.

- Solution:

- Replace the recoil assembly (a 20-minute DIY job with a 20–20–40 kit).

5. Environmental Factors: Cold, Altitude, and More

Symptoms:

- Hard starting in cold weather.

- Poor performance at high altitudes.

Common Fixes:

A. Cold Weather Challenges

- Why It Happens: Thick oil and poor fuel vaporization.

- Solution:

- Use winter-grade oil (5W-30).

- Close the choke while starting, then open it once the engine warms.

- Store the generator in a sheltered area.

B. High Altitude Adjustments

- Why It Happens: Thin air disrupts the air-fuel mixture.

- Solution:

- Re-jet the carburetor for higher elevations (see your manual).

- Adjust the carburetor’s mixture screw to lean out the fuel flow.

Quick-Reference Troubleshooting Checklist

Before panicking, run through this list:

- Fuel: Fresh gas? Stabilizer added? Fuel valve open?

- Spark Plug: Clean, gapped, and functioning?

- Oil: Level adequate? No sludge or debris?

- Air Filter: Unclogged and clean?

- Battery: Charged and corrosion-free?

- Kill Switch: In the “On” position?

- Circuit Breaker: Reset if tripped?

When to Call a Professional

While many fixes are DIY-friendly, some issues require expertise:

- Internal engine damage (e.g., bent rods, seized pistons).

- Electrical system failures (e.g., faulty voltage regulator).

- Persistent error codes on digital displays.

Preventive Maintenance: Avoid Problems Before They Start

- Monthly: Test-start the generator and check oil levels.

- Seasonally: Replace air filters, stabilize fuel, and inspect belts.

- Annually: Change oil, replace spark plugs, and load-test the unit.

Final Thoughts: Stay Prepared, Stay Powered

A generator that won’t start isn’t just an inconvenience – it’s a safety risk during emergencies. By understanding these common issues and adopting a proactive maintenance routine, you’ll ensure your generator is always ready to roar to life. Bookmark this guide, share it with fellow generator owners, and sleep soundly knowing you’re prepared for anything Mother Nature throws your way.

Download Our Free Tools:

- [Generator Maintenance Checklist]

- [Emergency Startup Cheat Sheet]