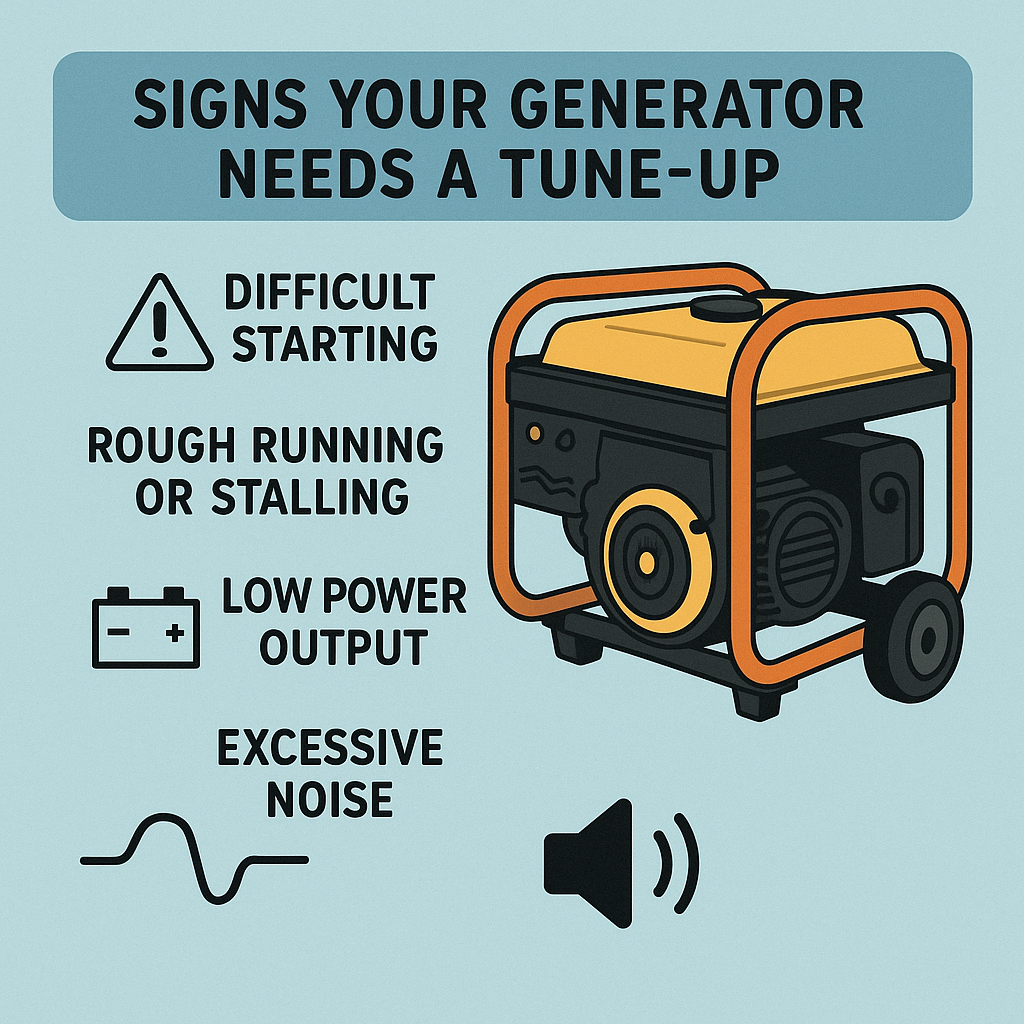

11 Warning Signs Your Generator Needs a Tune-Up (And What to Do Next)

A generator is more than just a backup power source—it’s your lifeline during storms, blackouts, or off-grid adventures. But like any machine, it can’t run forever without care. Ignoring subtle warning signs can lead to sudden breakdowns, costly repairs, or even dangerous malfunctions. To keep your generator reliable and ready, here’s a detailed guide to spotting the red flags that scream, “I need a tune-up!”

1. It Struggles to Start or Keeps Stalling

The Problem: If your generator cranks but won’t start, or starts briefly before dying, the issue likely lies in its fuel or ignition system. Stale fuel, clogged carburetors, or a worn spark plug are common culprits.

Why It Matters: A generator that won’t start defeats its purpose. Delayed starts during emergencies can leave you vulnerable.

What to Do:

- Check the fuel: Replace old gasoline (older than 30 days) and add a stabilizer.

- Clean the carburetor: Use a carburetor cleaner to dissolve varnish buildup.

- Test the spark plug: Replace it if corroded or fouled (a $5 fix that saves headaches).

Pro Tip: Portable generators stored for months often suffer from gummed-up carburetors. Consider installing a fuel shutoff valve to drain the carburetor before storage.

2. Flickering Lights or Unstable Power

The Problem: If your lights dim or electronics behave erratically, your generator’s voltage output is unstable. This could stem from a failing alternator, worn voltage regulator, or overloaded circuits.

Why It Matters: Unstable power can fry sensitive electronics like laptops, refrigerators, or medical devices.

What to Do:

- Test voltage: Use a multimeter to check output. For 120V systems, readings should stay between 110V–130V.

- Reduce the load: Avoid exceeding 80% of the generator’s max capacity.

- Call a pro: If voltage fluctuates at low loads, the alternator or AVR may need replacement.

Real-Life Example: A family running a space heater and microwave simultaneously noticed flickering lights—turns out their generator’s voltage regulator was failing. A $150 repair saved their appliances.

3. Strange Noises: Knocking, Grinding, or Squealing

The Problem: Unusual noises are your generator’s cry for help. Knocking may signal low oil, while grinding could mean bearing failure. Squealing often points to loose or worn belts.

Why It Matters: Ignoring these sounds can lead to catastrophic engine failure.

What to Do:

- Check oil levels immediately: Low oil is a top cause of engine damage.

- Tighten loose components: Use a wrench to secure bolts on the muffler, engine mounts, or covers.

- Replace belts: If belts are cracked or glazed, swap them out (a 20-minute DIY job).

Pro Tip: Record the noise with your phone to help mechanics diagnose the issue faster.

4. Excessive Smoke or Odd Smells

The Problem:

- Black smoke: Too much fuel (clogged air filter, rich fuel mixture).

- Blue/white smoke: Burning oil (leaky gaskets or worn piston rings).

- Burning plastic smell: Overheating wires or insulation.

Why It Matters: Smoke signals internal damage, while electrical smells can precede fires.

What to Do:

- Stop the generator immediately to prevent further damage.

- Inspect air filters: Replace if dirty.

- Check for oil leaks: Replace seals or gaskets.

- Examine wiring: Look for melted insulation or loose connections.

5. Fuel or Oil Leaks

The Problem: Puddles under your generator or strong gasoline odors indicate leaks. Cracked fuel lines, loose fittings, or degraded gaskets are likely suspects.

Why It Matters: Fuel leaks are fire hazards; oil leaks starve the engine of lubrication.

What to Do:

- Never run a leaking generator.

- Tighten fittings: Use a wrench to secure fuel line connections.

- Replace damaged parts: Swap out cracked hoses or oil pans.

Pro Tip: Use UV dye in oil to pinpoint hard-to-find leaks under a blacklight.

6. Dirty or Low Oil

The Problem: Oil turns sludgy over time, losing its ability to lubricate. Metal shavings in oil signal internal wear.

Why It Matters: Dirty oil accelerates engine wear and can trigger automatic shutdowns.

What to Do:

- Change oil ASAP: Follow your manual’s viscosity recommendations (e.g., 10W-30).

- Replace the oil filter: A clogged filter restricts oil flow.

Pro Tip: Keep spare oil and filters in your emergency kit—you’ll thank yourself during a storm.

7. Dead or Weak Battery (Standby Generators)

The Problem: Standby generators rely on batteries to auto-start during outages. Corroded terminals or old batteries prevent this.

Why It Matters: A dead battery = no automatic backup when the grid fails.

What to Do:

- Clean terminals: Scrub with baking soda and water.

- Test voltage: A healthy 12V battery should read 12.6–12.8V.

- Replace every 3–5 years: Even if it “seems” okay.

8. Sudden Spike in Fuel Consumption

The Problem: If your generator guzzles gas faster than usual, it’s working harder due to inefficiencies—like a clogged air filter or misadjusted carburetor.

Why It Matters: Wasted fuel costs money and strains the engine.

What to Do:

- Clean/replace air filters.

- Adjust the carburetor: Follow manual instructions for fuel-air mixture.

9. Age or High Runtime Hours

The Problem: Generators aren’t immortal. After 1,000+ hours or 10–15 years, components like piston rings and valves wear out.

What to Do:

- Track runtime hours: Many modern generators log this digitally.

- Schedule a professional inspection: For older units, a mechanic can assess wear and recommend rebuilds.

10. Overheating or Tripped Breakers

The Problem: Overheating warps engine parts, while tripped breakers indicate overloads or short circuits.

What to Do:

- Clean cooling fins: Use compressed air to blast away debris.

- Ensure ventilation: Keep 3–5 feet of clearance around the generator.

- Upgrade your unit: If tripping persists, you may need a higher-wattage model.

11. Error Codes or Warning Lights

The Problem: Modern generators display codes like “ERR 12” for voltage issues or “Low Oil” warnings.

What to Do:

- Decode the manual: Match the code to the problem.

- Reset the system: Sometimes, a simple reboot fixes glitches.

- Seek professional help: If codes recur, internal sensors or wiring may be faulty.

Proactive Tune-Up Checklist

- Monthly: Check oil levels, inspect for leaks, test startup.

- Every 6 Months: Replace air filters, clean spark plugs.

- Annually: Change oil/filters, load-test the generator, inspect belts/hoses.

- Every 3–5 Years: Replace batteries, coolant, and worn gaskets.

Final Thoughts: Don’t Wait for Disaster

Your generator’s reliability hinges on proactive care. By heeding these warning signs and sticking to a maintenance schedule, you’ll avoid costly repairs and ensure it’s always ready to power through emergencies. Remember: A generator tune-up isn’t a luxury—it’s insurance against chaos.

Need Help? Bookmark this guide, share it with fellow generator owners, or download our free [Generator Maintenance Checklist] to stay organized. Stay powered, stay safe!