33 Key Applications of Hydrogen Power and Leading Companies

As the global race toward net-zero intensifies, hydrogen energy is emerging as a vital clean energy solution — particularly for sectors where electrification alone is insufficient or impractical. Green hydrogen, produced from renewable energy sources via electrolysis, offers a truly sustainable alternative. It emits only water vapor when used and can store energy over long periods, making it ideal for replacing fossil fuels in high-heat industrial processes and heavy transport.

Hydrogen’s versatility makes it indispensable across a wide range of industries — from steelmaking to aviation, construction to residential heating. Below are 33 real-world applications that highlight how companies around the globe are already deploying hydrogen to decarbonize hard-to-abate sectors.

1. Hydrogen-Powered Trains (Alstom – Coradia iLint)

Rail transport is undergoing a quiet revolution with the introduction of hydrogen-powered trains. Alstom’s Coradia iLint is the world’s first zero-emission passenger train powered by hydrogen fuel cells. These trains convert hydrogen and oxygen into electricity, powering traction motors while emitting only water.

Since 2018, Coradia iLint trains have been operating in Lower Saxony, Germany, replacing diesel engines and saving up to 700 tonnes of CO₂ per train annually . This success has sparked global interest, with deployments planned or trialed in France, Italy, the UK, and Austria.

Key challenges include building hydrogen refueling infrastructure and reducing upfront costs. However, these early successes mark a significant step toward decarbonizing non-electrified rail lines.

2. Green Steel Production (ArcelorMittal)

Steel production is one of the most carbon-intensive industries globally. ArcelorMittal is leading the charge by replacing coal with green hydrogen in Direct Reduced Iron (DRI) processes. In this method, hydrogen reduces iron ore to sponge iron, producing water instead of carbon dioxide. When combined with Electric Arc Furnaces powered by renewables, this approach (known as DRI-EAF) can reduce emissions by up to 95% .

ArcelorMittal is constructing a 100,000-tonne/year DRI demonstration plant in Hamburg, Germany, directly fed by a 10 MW electrolyzer , with full-scale production expected by 2026 . Similar investments are underway in Canada, France, and Spain, all aiming for carbon neutrality by 2050 .

Challenges remain, including securing large volumes of affordable green hydrogen and managing high capital expenditures.

3. Hydrogen-Powered Trucks (Hyundai – XCIENT Fuel Cell)

For long-haul and heavy freight, hydrogen fuel cell trucks offer a compelling alternative to battery electric vehicles. Hyundai’s XCIENT Fuel Cell truck provides the range (over 400 km ), fast refueling (under 20 minutes ), and payload advantages that make it suitable for commercial operations.

In Switzerland, over 50 XCIENT trucks have been operating since 2020 , covering more than 7 million kilometers transporting goods for major retailers like Coop, Migros, and Galliker. Challenges include high vehicle costs and the limited availability of heavy-duty hydrogen refueling stations.

Despite these hurdles, hydrogen trucks represent a promising solution for decarbonizing freight logistics.

4. Data Center Backup and Prime Power (Microsoft)

Data centers require reliable, continuous power. Microsoft is exploring hydrogen fuel cells as a clean alternative to traditional diesel generators. In 2022 , the company successfully ran a 48-hour test on a 250 kW server rack array powered solely by hydrogen fuel cells at its Quincy, Washington data center campus. They are now deploying a 3 MW pilot system for extended backup.

Challenges include cost competitiveness with existing backup solutions and establishing reliable green hydrogen supply chains.

5. Sustainable Aviation Fuel & Direct Combustion (Airbus – ZEROe)

Airbus is pioneering two pathways to zero-emission flight using hydrogen:

- Producing synthetic drop-in Sustainable Aviation Fuels (SAF) via Power-to-Liquid (PtL) technology using green hydrogen.

- Directly burning liquid hydrogen in modified gas turbine engines or using fuel cells for propulsion in their ZEROe concept aircraft.

The company is developing ground demonstrators for liquid hydrogen tanks and propulsion systems and collaborating with airlines and airports (e.g., Air France-KLM, VINCI Airports) to prepare hydrogen infrastructure. Target entry-into-service is set for 2035 .

Challenges include cryogenic storage on aircraft, airport hydrogen infrastructure, and regulatory certification.

6. Maritime Transport Fuel (Maersk)

Maersk is decarbonizing shipping through hydrogen-derived e-fuels, specifically green methanol, which is produced by combining green hydrogen with captured CO₂.

The company has ordered 12 large dual-fuel container ships capable of running on green methanol. The first vessel, the Laura Maersk , entered service in 2023 . Maersk is actively securing e-methanol supply through partnerships, such as with European Energy for a facility in Denmark.

Challenges involve scaling green e-fuel production to meet massive shipping demand and reducing production costs.

7. Gas Network Blending (ENGIE – GRHYD)

A transitional strategy involves blending low percentages of hydrogen (e.g., 6–20% ) into natural gas pipelines to reduce the carbon intensity of delivered gas for heating and power.

The GRHYD project in Dunkirk, France, successfully demonstrated blending up to 20% hydrogen into the natural gas grid for over 100 homes and hydrogen-powered buses between 2018–2022 .

Challenges include material compatibility at higher blends, regulatory limits, and end-user appliance compatibility.

8. Construction Machinery (JCB)

JCB is decarbonizing off-road equipment by developing internal combustion engines modified to burn hydrogen instead of diesel, offering familiar performance and refueling options for operators.

The company has manufactured over 50 prototype hydrogen combustion engines and integrated them into machines like backhoe loaders and telescopic handlers. These prototypes are undergoing rigorous testing on construction sites.

A key challenge is developing on-site hydrogen refueling solutions for remote construction locations.

9. Residential Heating (Centrica)

Centrica is preparing homes for the hydrogen transition by offering hydrogen-ready boilers and micro-CHP units.

In 2021 , Centrica ran the UK’s first hydrogen home trial in Gateshead, demonstrating a hydrogen-ready boiler and appliances operating on 100% hydrogen . The company is also part of the H100 Fife project in Scotland, aiming to supply up to 300 homes with green hydrogen for heating by 2025 .

Challenges include large-scale hydrogen production for heating and the costs and safety standards associated with full network conversion.

10. Green Hydrogen Production (Siemens Energy)

Green hydrogen production is the foundation of the hydrogen economy. Siemens Energy focuses on large-scale Proton Exchange Membrane (PEM) electrolyzers, using renewable electricity to split water into hydrogen and oxygen.

An example includes supplying the 8.75 MW PEM electrolyzer for Shell’s Refhyne I project at the Rheinland refinery in Germany — one of the largest operational electrolyzers in Europe.

Collaborations with companies like Air Liquide aim to drive down costs through gigawatt-scale manufacturing. Challenges include reducing capital expenditure and operational energy consumption.

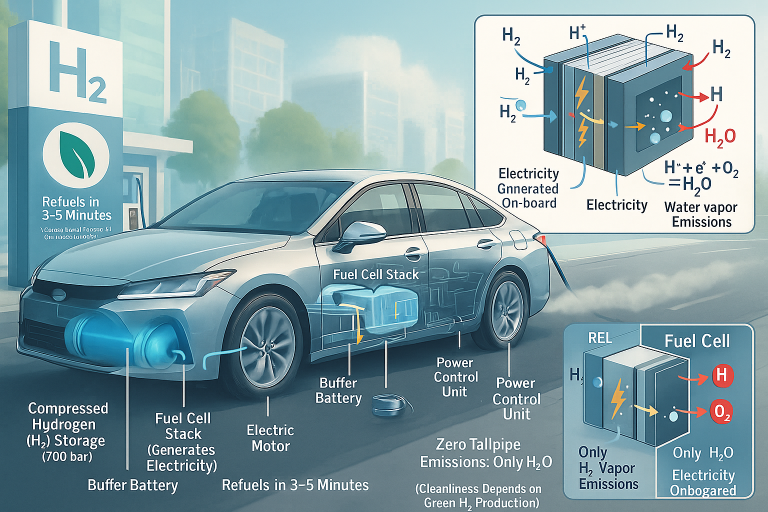

11. Passenger Vehicles (Toyota – Mirai)

Fuel cell electric vehicles (FCEVs) like the Toyota Mirai generate electricity onboard using hydrogen, offering long range and fast refueling.

Toyota has sold over 20,000 Mirai vehicles globally since its launch. California hosts the largest fleet, supported by a growing network of hydrogen stations. Taxi fleets, like those operated by Hype in Paris, utilize Mirais.

Challenges include achieving cost parity with battery electric vehicles (BEVs) and expanding the hydrogen refueling station network.

12. High-Temperature Industrial Heat (Thyssenkrupp)

Hydrogen can be burned directly in furnaces and kilns used in cement, lime, glass, and chemical production, replacing fossil fuels in processes requiring temperatures above 400°C .

Thyssenkrupp Steel successfully tested the injection of hydrogen into a blast furnace at its Duisburg site in 2019 , marking a significant step toward reducing coke consumption.

Challenges include high hydrogen demand concentration, furnace modification costs, and ensuring flame characteristics meet process requirements.

13. Hydrogen Storage & Transport (Hydrogenious LOHC Technologies)

Hydrogenious LOHC Technologies uses Liquid Organic Hydrogen Carriers (LOHCs) to bind hydrogen to an organic liquid at ambient conditions, solving logistics challenges.

The company operates a pilot plant in Erlangen, Germany, and is building a commercial-scale release plant at CHEMPARK Dormagen to supply hydrogen to the chemical industry.

Challenges include the energy penalty for the binding/release cycle and carrier costs.

14. Refueling Infrastructure (Air Liquide)

Air Liquide is a key player in deploying hydrogen refueling stations (HRS) for cars, trucks, and buses. Examples include supporting Hyundai’s fleet in Switzerland and the H2Haul project trucks across Europe.

They are also part of consortiums developing large public networks like H2 MOBILITY Deutschland.

Challenges include high station capital expenditure and achieving utilization rates for economic viability during early adoption.

15. Power-to-Gas / Seasonal Storage (Uniper)

Power-to-gas technology stores surplus renewable energy long-term by converting excess wind/solar power into hydrogen via electrolysis, which is then stored underground.

Uniper operates the HyStock pilot facility in Groningen, Netherlands, injecting hydrogen into underground salt caverns. The company is also developing the Green Wilhelmshaven import terminal and production hub in Germany.

Challenges include round-trip efficiency losses and large-scale cavern development costs.

16. Public Transport Buses (Van Hool)

Hydrogen fuel cell buses offer longer range and faster refueling than battery-electric buses, making them ideal for urban mobility.

Van Hool supplies buses to operators globally. Notable deployments include RVK in Cologne, Germany (over 30 buses ), and Aberdeen, Scotland — one of Europe’s first and largest hydrogen bus fleets.

Challenges include higher upfront costs compared to diesel or CNG buses, although total cost of ownership (TCO) is improving.

17. Green Ammonia Fertilizers (Yara)

Ammonia production is highly energy-intensive and traditionally relies on grey hydrogen. Yara is replacing this with green hydrogen to produce green ammonia.

At its Porsgrunn, Norway facility, Yara is building a 24 MW renewable hydrogen plant to produce approximately 20,000 tonnes of green ammonia annually , starting in 2026 .

Challenges include the high cost of green hydrogen versus grey hydrogen and scaling production.

18. Off-Grid & Portable Power (Intelligent Energy)

Intelligent Energy provides compact hydrogen fuel cell systems for off-grid telecom towers and other critical infrastructure.

These systems are in use with operators like Orange and Vodafone in Africa and Europe, replacing diesel generators.

Challenges include fuel logistics for remote locations and overall system cost.

19. Material Handling Equipment (Plug Power)

Plug Power leads the early hydrogen fuel cell market in material handling equipment, especially forklifts.

The company has deployed over 60,000 fuel cell units , primarily for forklifts, with major customers including Walmart, Amazon, BMW, and Home Depot.

A challenge lies in expanding beyond captive fleets to broader industrial equipment markets.

20. Pipeline Blending (SoCalGas)

SoCalGas is testing the feasibility of blending hydrogen into existing natural gas pipelines. Their “H2 Hydrogen Home” project in Downey, California, blends up to 20% hydrogen into a dedicated pipeline serving about 30 homes and commercial buildings .

Challenges include pipeline material embrittlement studies, compressor compatibility, and end-use appliance certification for higher blends.

21. Grid Balancing & Storage (Cummins/Hydrogenics)

Cummins supplies large-scale PEM electrolyzer systems for balancing the grid and providing multi-day/seasonal energy storage.

An example is the 20 MW PEM electrolyzer supplied for Air Liquide’s green hydrogen facility in Bécancour, Québec, Canada.

Challenges include system efficiency and cost competitiveness with other short-duration storage technologies.

22. Waste-to-Hydrogen (Ways2H)

Ways2H produces hydrogen from waste streams like sewage sludge and plastic using thermochemical processes.

The company built a demonstration plant in Tokyo, Japan, and is developing commercial plants in California and Portugal.

Challenges include process efficiency, syngas cleaning complexity, and scaling.

23. Long-Endurance Drones (Doosan Mobility Innovation)

Doosan’s hydrogen-powered drones enable extended flight times for commercial and industrial applications.

Used by KEPCO in South Korea for power line inspections and in coastal monitoring missions lasting over 2 hours , these drones demonstrate hydrogen’s potential in aerial applications.

Challenges include drone weight optimization and hydrogen cartridge handling/safety regulations.

24. Large-Scale Underground Storage (RAG Austria AG)

RAG Austria utilizes existing geological formations for hydrogen storage.

Their “Underground Sun Storage” pilot in Pilsbach injects hydrogen mixed with natural gas into depleted gas fields. A follow-up project called “Underground Sun Conversion” is underway.

Challenges include proving long-term integrity of reservoirs with pure hydrogen and managing cushion gas.

25. Air-Independent Propulsion (ThyssenKrupp Marine Systems)

Hydrogen fuel cells provide stealth and endurance for submarines. ThyssenKrupp Marine Systems’ Class 212A and 214 submarines operate with Siemens PEM fuel cells, allowing weeks of submerged operation.

Operated by navies in Germany, Italy, South Korea, and Greece, these vessels showcase hydrogen’s military utility.

Challenges include on-board hydrogen storage density and safety in confined spaces.

26. Food Manufacturing Process Heat (Nestlé)

Nestlé is piloting hydrogen burners for steam generation at its factory in Giruá, Brazil, as part of its net-zero roadmap.

Challenges include ensuring absolute purity of hydrogen to avoid food contamination and burner compatibility.

27. Mining Haul Trucks (Anglo American – nuGen)

Anglo American unveiled a 290-tonne hydrogen fuel cell/battery hybrid haul truck at its Mogalakwena platinum mine in South Africa in 2022 .

The company is building a green hydrogen production facility and refueling station on-site for a full pilot.

Challenges include developing ruggedized fuel cells and on-site hydrogen production/refueling in remote mines.

28. Critical Backup Power (Ballard Power Systems)

Ballard fuel cells provide emissions-free backup power for thousands of telecom towers globally.

They also power critical infrastructure like the FirstEnergy data center in the USA.

Challenges include fuel storage footprint and cost relative to incumbent technologies.

29. Integrated Green Steel (H2 Green Steel)

H2 Green Steel is building a fully integrated green steel plant in Boden, Sweden, featuring a 700 MW electrolyzer powered by Nordic hydropower and wind.

Target start-up is late 2025 , with annual production of 2.5 million tonnes of near-zero emission steel expected by 2026 .

Challenges include securing financing and proving large-scale integrated operations.

30. Residential Energy Storage (LAVO)

LAVO integrates hydrogen into home energy management systems.

Pilot systems are being tested in homes in Australia, including a government-supported trial in New South Wales, integrating with rooftop solar for multi-day storage.

Challenges include system cost, efficiency, and space requirements compared to lithium-ion batteries.

31. Glass Manufacturing Furnaces (Pilkington/NSG Group)

NSG Group has conducted trials using hydrogen blends in furnaces at its St Helens, UK plant.

Other manufacturers like Saint-Gobain are also running trials in Germany and France.

Challenges include maintaining glass quality, avoiding color changes, and furnace refractories compatibility.

32. Off-Grid Telecom Power (Ericsson)

Ericsson has deployed hydrogen fuel cell solutions — often hybridized with solar PV and batteries — for telecom towers in remote regions of Africa and Asia.

This significantly reduces diesel dependence.

Challenges include fuel logistics and system maintenance in remote areas.

33. Textile Processing Heat (Toyota Boshoku)

Toyota Boshoku is developing and testing dedicated hydrogen burners for textile drying processes within its own manufacturing facilities in Japan.

Challenges include burner flame characteristics and temperature profile matching for specific processes.

The Path Forward

These 33 applications , grounded in active projects and deployments from Germany to Sweden, California to South Korea, demonstrate hydrogen’s unique versatility as a clean energy vector.

While challenges around cost, infrastructure, scaling green production, and technology maturity remain significant, the momentum is undeniable.

Strategic partnerships, supportive policies (like the EU Hydrogen Strategy and US Hydrogen Hubs program), and relentless innovation are driving progress.

Hydrogen is not a silver bullet, but it is an essential piece of the decarbonization puzzle — especially for the hardest-to-abate sectors. The leadership shown by these companies underscores hydrogen’s critical role in building a sustainable, low-carbon future. The next decade will be pivotal in scaling these technologies from demonstration projects and initial deployments to mainstream commercial viability.