Kairos Power Achieves Critical Milestone with Installation of Third Test Reactor Vessel at Oak Ridge

On July 16, 2025, Kairos Power marked a pivotal advancement in next-generation nuclear technology by installing the reactor vessel for its third Engineering Test Unit (ETU 3.0) at the company’s Oak Ridge, Tennessee campus. This 14-foot-tall (4.3-meter) structure represents the latest evolution in Kairos Power’s iterative development strategy for its Fluoride Salt-Cooled High-Temperature Reactor (KP-FHR) technology. As Chief Technology Officer and co-founder Edward Blandford emphasized, this milestone “marks a significant moment on our commercial development pathway,” serving both as a testing platform for the Hermes demonstration reactor and as a foundation for future commercial deployment .

The installation coincides with Kairos Power’s progression under the U.S. Department of Energy’s Advanced Reactor Demonstration Program (ARDP), which selected KP-FHR as one of five technologies for federal risk reduction funding in 2020. The DOE has committed up to $303 million in performance-based payments tied to milestone achievements, a structure CEO Mike Laufer credits for enabling agility while demonstrating responsible stewardship of public funds .

Technical Innovations and Manufacturing Breakthroughs

The ETU 3.0 reactor vessel showcases cutting-edge manufacturing techniques critical to Kairos Power’s cost-reduction mission:

- Electron Beam Welding (EBW) Technology: Fabricated through a partnership with Cambridge Vacuum Engineering and the University of Sheffield’s Advanced Manufacturing Research Centre, EBW enables welds at least 10x faster than conventional arc welding while maintaining exceptional precision. This method addresses nuclear construction’s demanding tolerances and scales efficiently for future commercial production .

- Iterative Design Refinement: ETU 3.0 builds on lessons from prior test units:

- ETU 1.0 (2021–2023): Validated salt chemistry and thermal hydraulics with 2,000+ hours of pumped FLiBe (fluoride-lithium-beryllium) coolant operations.

- ETU 2.0 (completed January 2025): Pioneered in-house vessel manufacturing at Kairos Power’s Albuquerque facility, achieving 80% vertical integration with commercial off-the-shelf parts .

| Generation | Key Achievements | Primary Focus |

|---|---|---|

| ETU 1.0 | 2,000+ hours of FLiBe salt operations | System integration, salt chemistry validation |

| ETU 2.0 | First internally fabricated reactor vessel | Modular construction, vertical integration |

| ETU 3.0 | EBW-fabricated vessel; operator training | Advanced manufacturing; Hermes support |

Construction Strategy: Building Around Innovation

Kairos Power is employing a radical construction sequence for ETU 3.0’s facility. Partnering with Barnard Construction, the building is being erected around the reactor vessel—a reverse of conventional nuclear construction. This allowed the oversized component to be positioned before the roof installation, streamlining assembly and minimizing scheduling risks. The approach serves as a “proving ground” for refining methods for the Hermes Low-Power Demonstration Reactor, currently under construction adjacent to ETU 3.0 .

The Multifaceted Mission of ETU 3.0

Though non-nuclear, ETU 3.0 will deliver critical functions:

- Advanced Manufacturing Pilot: Testing modular component production to slash costs for future reactors.

- Hermes Support Hub: Housing a Modular Systems Facility to stage, assemble, and test equipment before Hermes installation .

- Operator Training Center: Simulating high-temperature reactor maintenance to improve safety and reduce downtime.

- Remote Handling Validation: Qualifying robotic systems for fuel handling and component replacement .

The Road to Commercialization: Hermes and Beyond

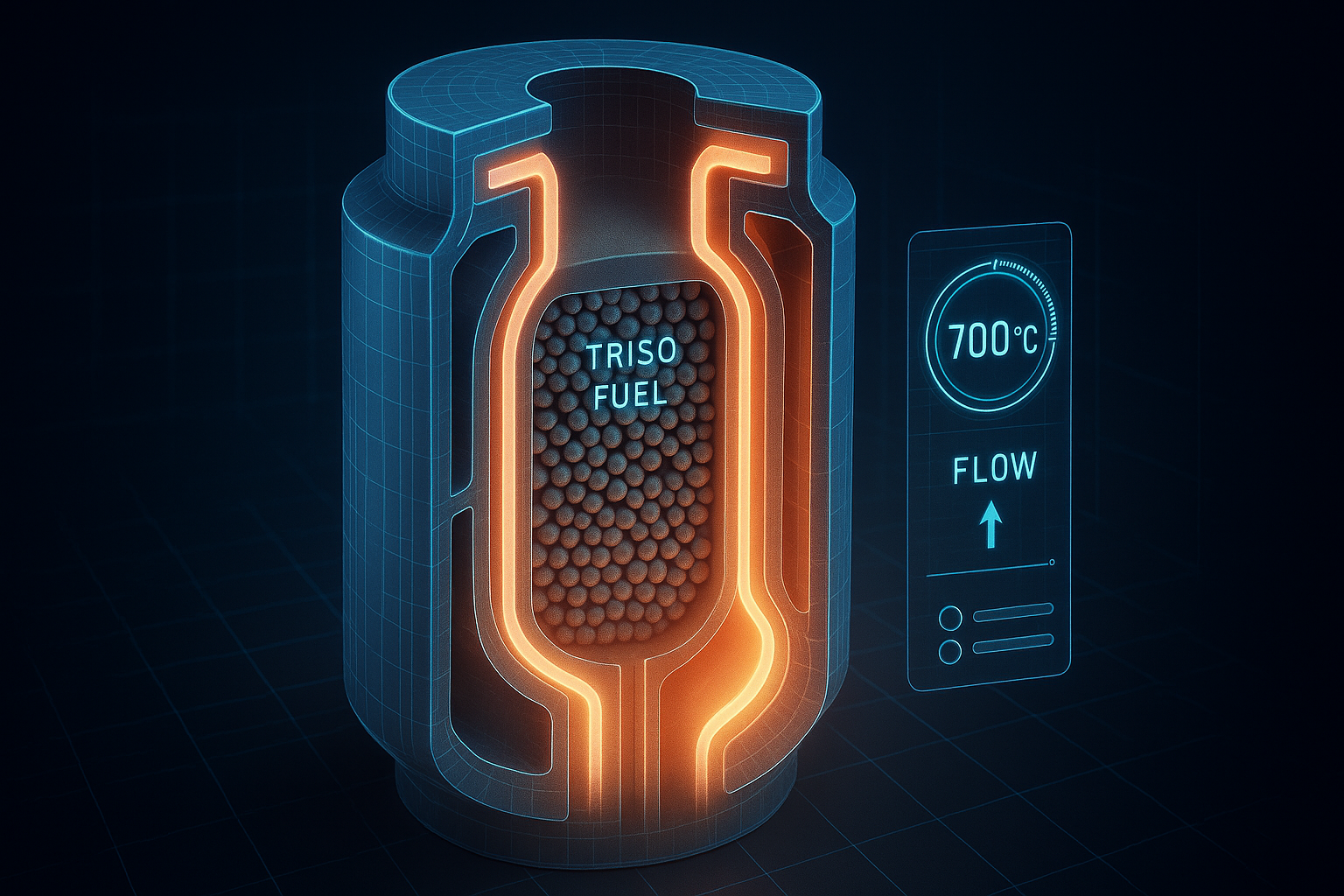

ETU 3.0 directly informs Kairos Power’s flagship Hermes reactor—the first non-light-water reactor permitted by the U.S. Nuclear Regulatory Commission in over 50 years. Hermes (35 MWt) will use TRISO pebble fuel immersed in FLiBe molten salt, demonstrating passive safety and thermal output without electricity generation. Its successor, Hermes 2—a two-unit plant with power generation—received NRC construction permits in November 2024 .

| Reactor | Capacity | Key Features | Status |

|---|---|---|---|

| Hermes | 35 MWt | TRISO fuel + FLiBe coolant; no power generation | Under construction (Oak Ridge) |

| Hermes 2 | 2 × 35 MWt | Adds power generation system | Permit issued (Nov 2024) |

| Commercial KP-FHR | ~2030s | Full-scale deployment | Targeting early 2030s |

Strategic Implications and Industry Impact

Kairos Power’s vertical integration strategy—exemplified by ETU 3.0’s manufacturing innovations—aims to disrupt nuclear economics. By internalizing production of specialized components like reactor vessels, the company gains control over cost, quality, and schedule—a stark contrast to traditional nuclear supply chains. As VP of Manufacturing Craig Gerardi notes, testing methods with non-nuclear iterations is a “game-changer” for establishing supply chain confidence .

Internationally, electron beam welding partners highlight broader implications. Ben Morgan of the University of Sheffield AMRC calls large demonstrations like ETU 3.0 “vital for bringing advanced manufacturing into industry,” while CVE’s Bob Nicolson notes EBW’s “transformative potential” for small modular reactor (SMR) commercialization .

The Future Timeline

With ETU 3.0 operational by late 2025, Kairos Power remains on track for:

- 2026–2027: Hermes operational testing

- 2028–2029: Hermes 2 construction and commissioning

- Early 2030s: Deployment of commercial KP-FHR reactors

Kairos Power’s ETU 3.0 represents more than a single reactor vessel—it embodies a new paradigm for nuclear development. By merging rapid iteration, advanced manufacturing, and modular construction, the project accelerates a critical mission: delivering inherently safe, cost-competitive nuclear energy to decarbonize global energy systems.