How to Prevent Fuel Tank Contamination in Generators

If you’ve ever had a generator stop working when you needed it most, you’re not alone. One of the biggest reasons generators break down is because their fuel tanks get dirty or contaminated.

Why Should You Care?

Fuel tank contamination is like a sneaky villain that ruins generators from the inside. It’s responsible for over 70% of generator breakdowns. Fixing these problems can cost $2,500 or more, but preventing them only costs about $200 per year. By following this guide, you’ll:

- Make your generator last longer.

- Keep the power on when you need it.

- Avoid expensive repairs.

Sounds good, right? Let’s dive in!

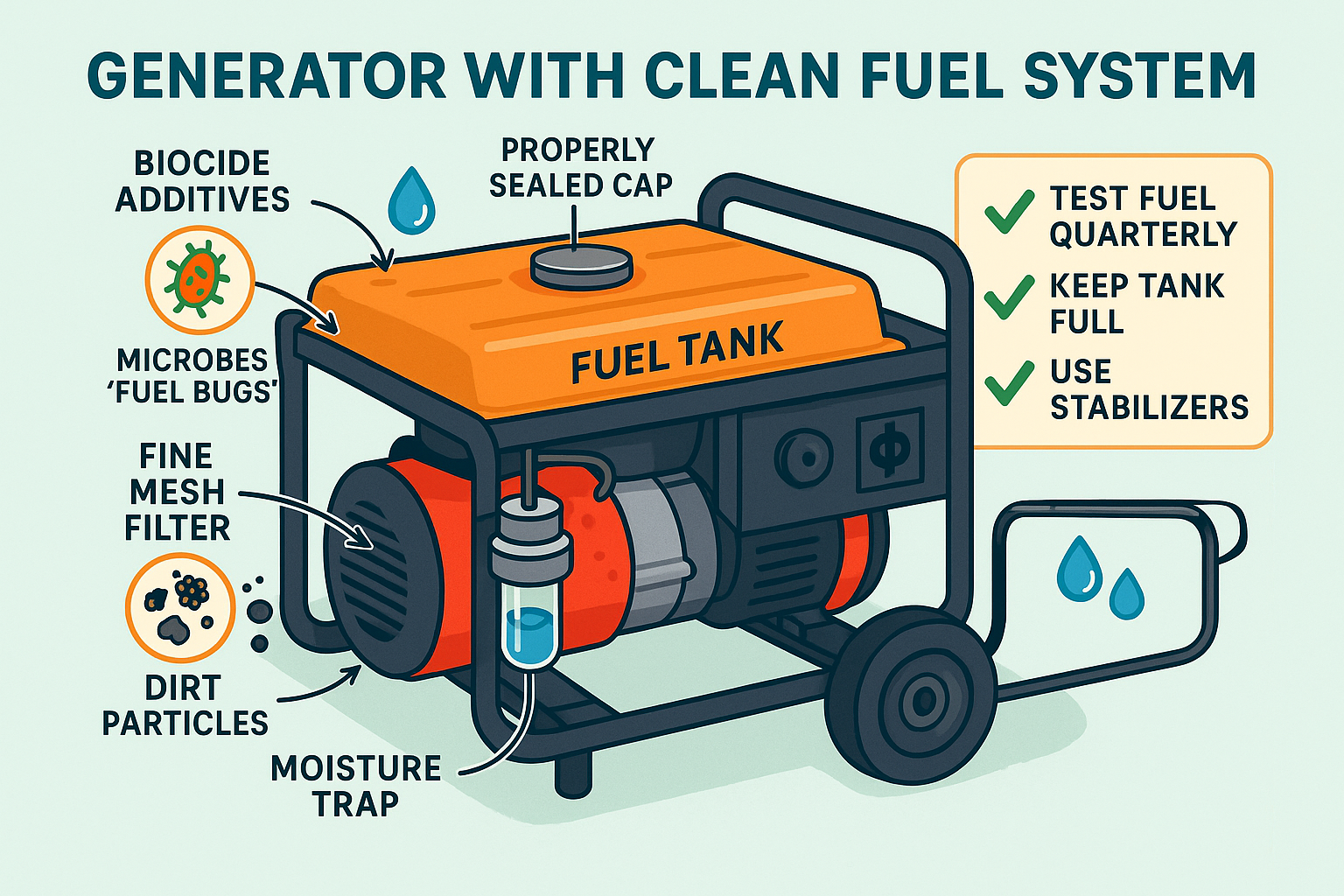

What Messes Up Fuel Tanks?

There are several things that can contaminate your generator’s fuel. Here’s a quick rundown:

1. Water

Water is the #1 enemy of fuel. It gets into tanks through:

- Condensation (when temperatures change).

- Rainwater sneaking in through vents or loose caps.

- Low-quality fuel deliveries.

Why it’s bad: Water causes rust, supports “fuel bugs” (microorganisms), and makes your generator less efficient.

2. Dirt and Particles

Dust, sand, rust flakes, or even paint chips can get into the fuel. This happens when:

- The fuel cap isn’t sealed properly.

- The tank lining is old and falling apart.

Why it’s bad: These particles can clog filters, wear out pumps, and damage injectors.

3. Microorganisms (“Fuel Bugs”)

These tiny critters grow where water and fuel mix. They create sludge and acids that corrode your system.

Why it’s bad: Sludge blocks filters and damages the engine.

4. Old or Bad Fuel

Over time, fuel goes bad:

- Gasoline forms gunk and separates into layers.

- Diesel turns into thick sludge.

- Propane loses its smell (which makes leaks harder to detect).

Why it’s bad: Bad fuel doesn’t burn properly and can ruin your generator.

5. Secondary Damage

Contaminated fuel harms other parts of the generator:

- Ethanol in gasoline eats rubber seals.

- Dirt particles destroy injectors and pumps.

- Sludge messes with sensors and fuel lines.

| Contaminant | How It Gets In | Impact on Generator |

|---|---|---|

| Water | Condensation, rain ingress, poor fuel quality | Microbial growth, rust, reduced combustion efficiency |

| Particulates (Dirt) | Open fill ports, poorly sealed caps, deteriorating tank linings | Abrasion of pumps/injectors, blocked filters, reduced fuel atomization |

| Microorganisms | Water-fuel interface in diesel tanks | Sludge formation, corrosive by-products, filter clogging, system corrosion |

| Degraded Fuel | Oxidation, thermal stress, ethanol separation | Varnish/gum buildup (gasoline), asphaltene precipitation (diesel), odorant fade (propane) |

How to Prevent Problems

Now that we know what causes contamination, let’s talk about how to stop it.

For Diesel Generators:

- Keep the tank almost full (>90%) to reduce condensation.

- Add a biocide (like Biobor JF) every 3 months to kill fuel bugs.

- Use fine filters (2-micron) to catch tiny particles.

- If storing fuel long-term, use a fuel polishing system to clean it regularly.

For Gasoline Generators:

- Use ethanol-free fuel if possible.

- Add a stabilizer (like Sta-Bil) to keep the fuel fresh.

- Don’t let fuel sit for more than 30 days—replace it often.

- Store fuel in sealed containers to keep air out.

For Propane/LPG Generators:

- Install moisture traps and sediment filters on regulators.

- Make sure the tank is upright to avoid liquid withdrawal.

- Check hoses and seals regularly for leaks.

| Fuel Type | Prevention Tips | Frequency |

|---|---|---|

| Diesel | Keep tank >90% full, use biocides (e.g., Biobor JF), install 2-micron filters, fuel polishing for storage | Every 3 months |

| Gasoline | Use ethanol-free fuel, add stabilizers (e.g., Sta-Bil), rotate or replace fuel every 30 days | Monthly |

| Propane/LPG | Install moisture traps, ensure correct tank orientation, inspect hoses/seals regularly | Regular inspections |

Special Tips for Different Uses:

- Standby Generators: Install vent screens and check fuel every 3 months.

- Portable Generators: Always secure the fuel cap and don’t let fuel sit too long.

- Cold Climates/Marine Use: Use anti-gelling additives and corrosion inhibitors.

Smart Maintenance Tips

Prevention is key! Here’s how to stay ahead of problems:

1. Test Your Fuel Regularly

- Use special pastes (like Aqua-Glo) to check for water.

- Send samples to a lab for detailed testing.

- Aim for less than 200 parts per million (ppm) of water and no microbial growth.

2. Upgrade Your Tank Setup

- Use double-walled tanks with sloped bottoms to drain water easily.

- Install fine mesh screens on vents to keep dirt out.

- Add level sensors with alarms to detect leaks.

3. Filter and Polish Your Fuel

- Use mobile systems to clean fuel before it enters the generator.

- Install inline filters with water sensors to catch contaminants.

- For big tanks, set up a recirculation loop to keep fuel moving and clean.

4. Buy Good-Quality Fuel

- Only buy from trusted suppliers who provide Certificates of Analysis (CoAs).

- Inspect fuel visually before storing it.

- Avoid suppliers without closed-loop delivery systems.

| Type | Example | Use Case | Frequency |

|---|---|---|---|

| Biocide | Biobor JF® | Diesel microbial control | Every 90 days |

| Stabilizer | Sta-Bil 360® | Gasoline oxidation/ethanol prevention | Monthly |

| Anti-gel | Power Service® | Cold diesel environments | Winter months |

What to Do If Things Go Wrong

Even with prevention, problems can still happen. Here’s how to fix them:

Signs Something’s Wrong:

- Hard starts or rough idling.

- Discolored fuel.

- Excessive smoke from the exhaust.

How to Fix It:

- For diesel: Treat with biocide and polish the fuel.

- For gasoline: Drain the tank, flush the carburetor, and replace filters.

- For sludge: Use a chemical cleaning system to break it down.

Disposing of Bad Fuel:

- Follow EPA rules for hazardous waste disposal.

- Use licensed handlers and keep records.

Cool Tools and Tech

Modern tools make fuel management easier:

- IoT Systems: Devices like Piusi Tank Guardian send alerts if something’s wrong.

- Advanced Filters: Magnetic filters catch metal particles, while centrifugal separators remove water and dirt without needing new filters.

Real-Life Examples

- Data Center Save: A 500kW backup generator was saved from a $46,000 breakdown by using a fuel polishing system.

- Hospital Outage: A hospital lost power during an outage because they didn’t test or treat their fuel for 2 years. Cost? $18,000 in repairs and 16 hours of downtime.

Follow the Rules

Make sure you comply with regulations like:

- EPA SPCC: Requires secondary containment for large tanks.

- NFPA 110: Says emergency generators must test fuel every 6–12 months.

- UL Standards: Ensure tanks and filters meet safety requirements.

Maintenance Schedule

| Task | Frequency | Details |

|---|---|---|

| Fuel Testing | Quarterly | Check for water (<200 ppm), microbial growth, and fuel quality |

| Tank Inspection | Monthly | Visual checks, water bottom inspection |

| Filter Replacement | Quarterly | Inspect and replace filters as needed |

| Generator Exercise Runs | Monthly | Run generator for 60+ minutes under >30% load |

| Professional Cleaning | Annually | Full tank cleaning or fuel polishing |

Final Thoughts

Keeping your generator’s fuel tank clean is simple if you follow these rules:

- “Water is the enemy – keep it out.”

- “Fuel degrades – rotate or treat it.”

- “Test quarterly – act immediately.”

By taking care of your fuel, you’ll save money, avoid headaches, and ensure your generator works when you need it most.

Remember: Clean fuel = happy generator!