How to Fix a Generator That Won’t Start (Recoil Starter Issues): The Ultimate Repair Guide

A generator that won’t start due to recoil starter issues is a common frustration for owners of portable units. The recoil starter (or pull-start system) manually engages the engine’s crankshaft to initiate combustion. When this mechanism fails—whether from a jammed rope, broken spring, or damaged pawls—the generator becomes unusable. Recoil-specific problems cause 40% of no-start scenarios in gas-powered generators, often stemming from wear, environmental damage, or improper handling . This guide details diagnosing and fixing these issues safely, covering everything from basic rope replacement to complex internal repairs.

How a Recoil Starter Works: Mechanics Simplified

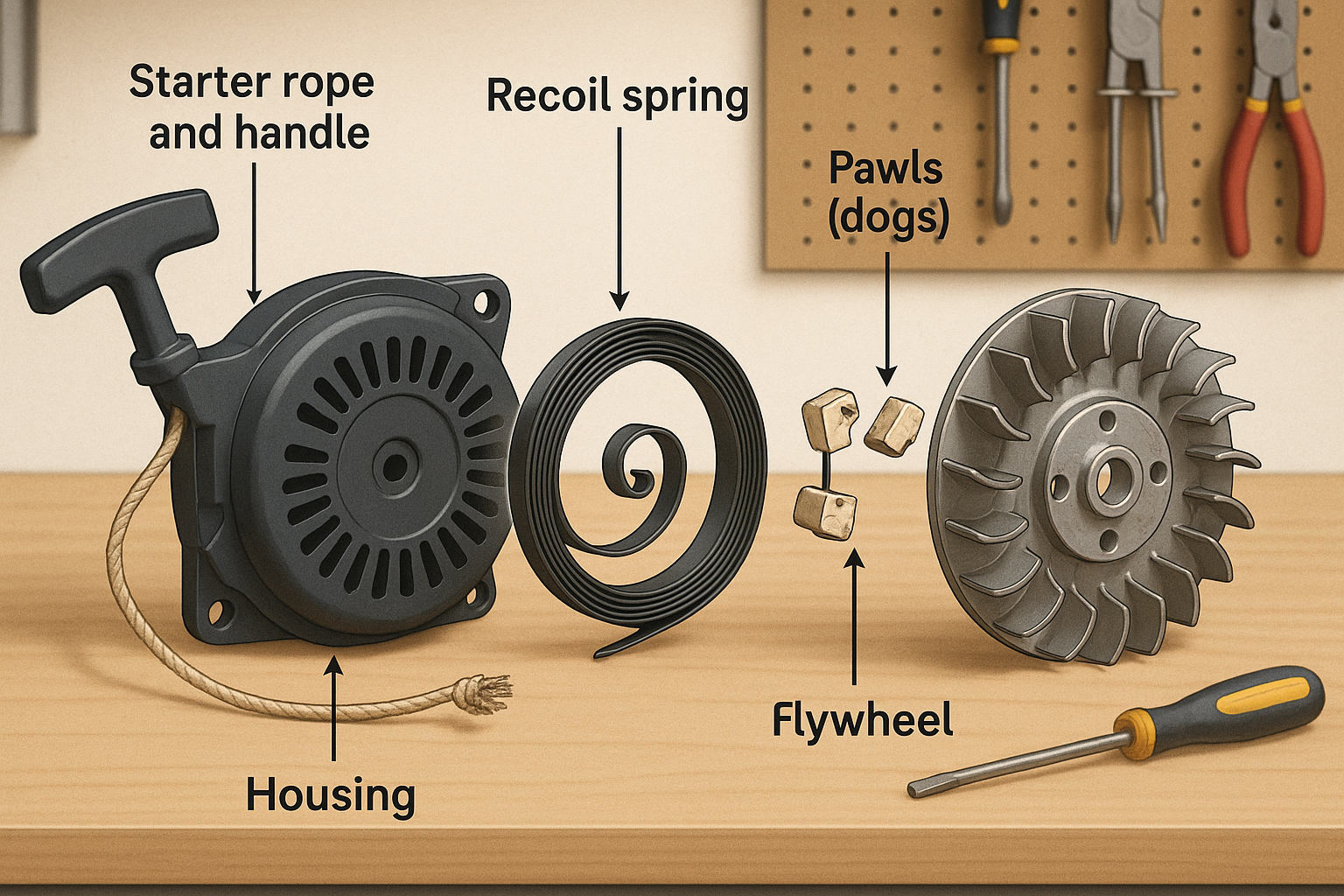

The recoil starter converts your pull force into rotational energy for the engine. Key components include:

- Starter Rope & Handle: User-pulled cord, typically 3–5 feet long.

- Pulley & Recoil Spring: Spool assembly that winds/unwinds the rope; the spring retracts it.

- Pawls (“Dogs”): Metal tabs that engage the flywheel teeth when the rope is pulled.

- Flywheel: Engine component that spins the crankshaft when engaged .

Operation Sequence:

- Pulling the rope extends the pawls to grip the flywheel.

- The flywheel rotates the crankshaft, triggering ignition.

- Releasing the rope retracts it via the spring, disengaging the pawls .

Tools and Safety Equipment

| Tools | Safety Gear | Replacement Parts |

|---|---|---|

| Phillips/flathead screwdrivers | Safety goggles | Replacement rope (1/8″ diameter) |

| Socket wrench set (8–10mm) | Work gloves | Recoil spring or pawl kit |

| Needle-nose pliers | Dust mask | Lubricant (WD-40 or silicone spray) |

| Wire cutters | Closed-toe shoes | Clean rags & degreaser |

Always use manufacturer-approved parts (e.g., BISON or HIPA recoil kits) for compatibility .

Safety Precautions

- Disconnect the spark plug wire to prevent accidental engine starts .

- Let the generator cool for 30+ minutes if recently run.

- Work on a flat, dry surface to avoid slips or tipping.

- Wear gloves to protect against sharp springs—recoil springs can snap violently if mishandled .

Symptoms and Associated Causes

| Symptom | Likely Culprits |

|---|---|

| Rope won’t pull | Seized engine, hydrolock, jammed pulley |

| Rope pulls freely (no resistance) | Disengaged pawls, broken flywheel key |

| Rope retracts partially | Worn recoil spring, binding rope |

| Grinding/clicking noises | Damaged flywheel teeth, misaligned pawls |

| Engine turns but won’t start | Non-recoil issue: Fuel/carburetor problems |

Troubleshooting & Fixes

A. Rope Won’t Pull

- Hydrolock Fix: Remove the spark plug. If liquid (fuel/oil/water) sprays out, dry the cylinder with a rag. Pull the rope repeatedly to expel residue. Check oil levels and carburetor float valve .

- Seized Engine Test: Attempt to rotate the flywheel manually via cooling fins. If stuck, internal engine damage is likely .

- Debris Removal: Inspect the flywheel area for obstructions (e.g., rodent nests, dirt) .

B. Rope Pulls But Doesn’t Engage Engine

- Remove the recoil housing (typically 3–4 bolts).

- Pawl Inspection: Clean pawls with degreaser. If broken or stuck, replace them. Test spring tension—pawls should snap outward when the rope is pulled .

- Flywheel Check: Damaged teeth require flywheel replacement.

C. Rope Doesn’t Retract

- Spring Re-tensioning:

- Unwind the rope from the pulley.

- Rotate the pulley counterclockwise 4–6 turns (maintain tension with pliers).

- Secure the pulley, rethread the rope, and test retraction .

- Broken Spring Replacement: Use a recoil repair kit matching your generator model.

D. Engine Turns But Won’t Start

While not recoil-related, these often accompany pull-start failures:

- Check spark plug for fouling/corrosion.

- Verify fresh fuel and clean carburetor jets.

- Inspect air filter for clogs .

Recoil Starter Removal & Inspection

- Disconnect the spark plug.

- Remove recoil housing bolts using a 10mm socket.

- Critical Checks:

- Rope: Fraying or knots causing binding.

- Spring: Rust, cracks, or detachment from the housing.

- Pulley: Cracks or uneven rope grooves.

- Pawls: Stiff movement or worn edges.

- Clean components with brake cleaner and lubricate pawls lightly .

Rope Replacement Guide

- Select Correct Rope: Use calipers to measure old rope diameter (usually 5/32″ or 3/16″). Cut new rope to match length .

- Threading Steps:

- Melt rope ends with a lighter to prevent fraying.

- Feed through the pulley hole and tie a stopper knot.

- Wind rope clockwise onto the pulley under spring tension.

- Pass through housing guides and handle; secure with a knot.

- Tension Test: Pull smoothly—retraction should be even and snag-free .

When to Replace the Entire Recoil Assembly

Consider a full replacement ($15–$40) if:

- The housing is cracked or mounting points are broken.

- Multiple components (spring + pawls + pulley) are damaged.

- Spring repeatedly slips despite re-tensioning .

Cost tip: Kits like HIPA’s recoil starter offer OEM-compatible parts for Champion/Honda models.

Common Mistakes to Avoid

- Releasing Spring Uncontrolled: Use pliers to handle the pulley during disassembly.

- Ignoring Spark Plug Disconnect: Risk of accidental engine ignition.

- Wrong Rope Size: Causes binding or premature wear.

- Over-tightening Housing Bolts: Warps plastic housings; snug evenly .

Environmental Factors

- Cold Weather: Thickens oil, increasing pull resistance. Use synthetic oil and store indoors.

- Moisture & Rust: Causes pawls/springs to seize. Apply silicone spray to metal parts.

- Rodent Damage: Nesting in unused generators jams mechanisms. Use mothballs or sealed storage .

Preventive Maintenance

| Task | Frequency |

|---|---|

| Inspect rope for fraying | Before each use |

| Lubricate pawls & spring | Every 3 months |

| Clean flywheel area | Monthly |

| Test recoil smoothness | Weekly (if used frequently) |

| Always store the generator level to prevent oil/fuel leaks into the cylinder . | Always |

When to Call a Professional

Seek expert help for:

- Engine seizures (persistent resistance after hydrolock fix).

- Internal camshaft/compression release failures (requires engine disassembly).

- Electrical issues (e.g., starter solenoid problems masking as recoil faults) .

Conclusion

Most recoil starter failures—stuck ropes, detached springs, or worn pawls—are repairable with basic tools and methodical troubleshooting. Prioritize safety by disconnecting the spark plug, and address environmental factors like moisture to prevent recurring issues. For complex repairs, leverage OEM kits from brands like BISON or HIPA . Remember: 90% of recoil issues can be resolved in under 30 minutes, restoring reliable starts for your generator during critical outages.

🔧 Pro Tip: Film your disassembly process with a smartphone to simplify reassembly.