How to Connect Two Generators in Parallel (Without Damaging Them): The Ultimate Guide

Connecting generators in parallel—the process of synchronizing two or more units to function as a single power source—transforms how users access electricity for homes, jobsites, and outdoor activities. By combining outputs, you gain higher total wattage without sacrificing portability, along with built-in redundancy if one unit fails. However, this powerful technique demands strict adherence to safety protocols and technical compatibility to prevent equipment damage, electrical fires, or hazardous backfeeding.

This guide details every phase of parallel operation: from selecting compatible generators and calculating loads to step-by-step synchronization and advanced troubleshooting. Whether you’re an RV enthusiast needing climate control or a homeowner preparing for storms, mastering these principles ensures reliable, scalable power.

Best Products for Connecting Two Generators in Parallel

| Product | Description | Amazon Link |

|---|---|---|

| Champion Generator Parallel Kit | Allows safe parallel connection of two compatible Champion generators | View on Amazon |

| WEN Parallel Connection Kit | Easy-to-use kit for pairing WEN inverter generators | View on Amazon |

| Heavy-Duty Generator Cables (30A/50A) | Reliable cables for high-current parallel connections | View on Amazon |

What Is Generator Paralleling? Core Concepts & Benefits

Definition and Electrical Principles

- Parallel Operation: Physically and electrically linking generators so their outputs synchronize to feed a common load. This requires matching voltage (e.g., 120V), frequency (60 Hz in North America), and phase angles (typically single-phase for portable units) .

- Power Output Dynamics: Voltage remains constant (e.g., 120V), while amperage combines. For example:

- Two 2,000W generators = 4,000W total capacity

- Voltage stays at 120V, but current doubles from ~16.7A to ~33.3A .

Key Advantages

- Scalability: Add smaller units as power needs grow, avoiding costly replacements .

- Fuel Efficiency: Run only the generators needed for the load, reducing idle consumption by 20–40% .

- Redundancy: Critical for hospitals or data centers—if one generator fails, others maintain power .

- Portability: Two 50-lb generators are easier to transport than one 150-lb unit .

Generator Types & Compatibility: What Works Together?

Inverter vs. Conventional Generators

Table: Comparison for Parallel Readiness

| Feature | Inverter Generators | Conventional Generators |

|---|---|---|

| Parallel Compatibility | Designed for it; built-in ports | Rarely supported; risky |

| Synchronization | Automatic; digital control | Manual; requires synchroscope |

| Waveform Stability | Clean THD (<3%); safe for electronics | High THD (15–25%); may damage devices |

| Noise Level | 50–60 dBA (quieter) | 70–85 dBA (louder) |

| Examples | Honda EU2200i, WEN GN6000i | Most construction-site generators |

- Inverter Generators: Ideal for paralleling. Their electronic throttling adjusts engine speed to load, while microprocessors sync voltage/frequency automatically via parallel cables .

- Conventional Generators: Paralleling requires manual synchronization using a synchroscope and load-sharing controllers. Mismatched phases can cause destructive circulating currents .

Brand and Model Compatibility

- Same Brand/Model: Strongly recommended. Identical units share control protocols (e.g., WEN’s GNA50i kit for 120V models) .

- Different Sizes (Same Brand): Possible but inefficient. A 3,000W + 5,000W pair can only deliver 6,000W total (not 8,000W), with loads split proportionally (e.g., 60%/40%) .

- Cross-Brand Pairings: Avoid unless manufacturers explicitly approve. Differing voltage regulation or communication signals can cause failures .

Essential Tools & Equipment

Parallel Kits & Accessories

- Manufacturer-Specific Kits: E.g., Honda Parallel Kit (for EU series), WEN GNA50i. Includes cables with proprietary connectors to prevent incorrect hookups .

- Heavy-Duty Cables: For DIY setups, use 10-gauge copper cables rated for 30A+ .

- Monitoring Tools:

- Voltmeter/ammeter to verify matched voltage (±5%) and frequency .

- Synchroscope for conventional generators (ensures phase alignment within 5°) .

- Transfer Switch: Critical for home backup systems to isolate generators from the grid .

Safety Gear

- Insulated gloves, arc-flash goggles

- Fire extinguisher (ABC-rated)

- Carbon monoxide detector (generators must be outdoors!)

Pre-Connection Safety Checks

- Generator Inspection:

- Confirm identical voltage/frequency ratings (e.g., 120V/60Hz).

- Check oil levels and fuel quality—contaminated fuel causes 70% of startup failures .

- Grounding:

- Drive an 8-ft copper grounding rod into soil.

- Connect generators using 6-gauge wire to prevent electrocution .

- Environment:

- Place generators on level ground, 3–5 feet apart for airflow.

- Keep 20+ feet from buildings to avoid CO buildup .

Power Calculation & Load Planning

Key Formulas

- Total Wattage: Gen A (rated watts) + Gen B (rated watts). Deduct 10% for buffer.

- Amperage Calculation: Amps = Total Watts / Voltage (e.g., 4,000W / 120V = 33.3A).

Load Management Strategies

- Surge Handling: Motor-driven devices (ACs, fridges) need 3x running watts at startup. Ensure combined surge capacity covers peaks .

- Balanced Distribution: Split high-watt devices between generators. Never exceed a single unit’s capacity—even in parallel .

Example Scenario:

Two 2,000W generators powering an RV:

- Running Loads: AC (1,200W) + fridge (600W) = 1,800W (safe).

- Surge Load: AC startup (3,600W) risks overloading one generator. Solution: Stagger high-load device startups.

Step-by-Step Parallel Connection Guide

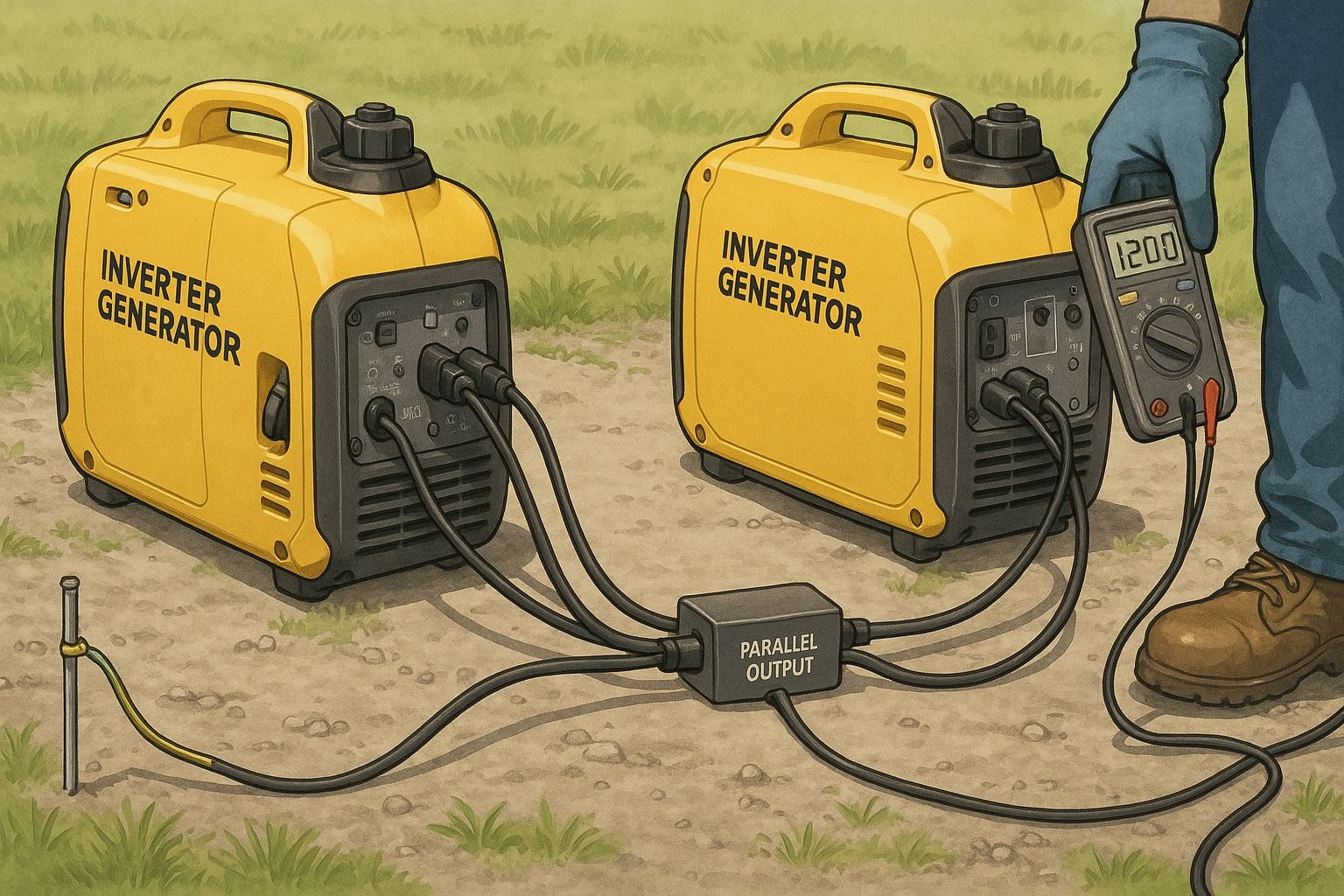

For Inverter Generators (with Kits)

- Setup: Position generators on level surfaces, connect grounding wires .

- Cable Connection:

- Plug red/black cables into parallel ports (color-matched).

- Secure grounding wires to terminals .

- Start Sequence:

- Start Generator 1; let it stabilize (1–2 minutes).

- Start Generator 2; LEDs on kits often indicate sync status.

- Load Connection:

- Plug devices into the parallel kit’s outlets—not individual generators.

- Gradually add loads (e.g., turn on lights before AC).

For Conventional Generators (Advanced)

- Synchronization:

- Use a synchroscope to match frequency and phase angle.

- Adjust Generator 2’s governor until the synchroscope needle rotates slowly clockwise .

- Breaker Closure: Close the paralleling breaker when phases align (12 o’clock position).

- Load Sharing: Manually balance loads using ammeters to ensure neither unit exceeds 80% capacity.

Real-World Use Cases

- Camping/RVs: Pair two 2,200W inverters to run air conditioning without noise penalties .

- Construction Sites: Connect conventional generators via paralleling switchgear for welding equipment (requires UL-certified kits) .

- Home Backup: During outages, two 10kW generators power a transfer switch-fed panel, covering essentials like wells and refrigerators .

- Off-Grid Solar Hybrids: Solar inverters (e.g., Solis) sync with generators during low-sun periods, reducing fuel use by 40% .

Common Mistakes & How to Avoid Them

- Mismatched Voltages/Frequencies: Causes circulating currents that overheat windings. Fix: Use identical models .

- Skipping Grounding: Risks electrocution. Fix: Always use a grounding rod .

- Direct Outlet Loading: Plugging devices into generators before syncing destabilizes the system. Fix: Use only the parallel kit’s outlets .

- Overloading One Unit: A 3,000W generator paired with a 5,000W unit will trip if handed 4,000W alone. Fix: Balance loads proportionally .

⚠️ Critical Safety Note: Never backfeed generators into wall outlets (“suicide cords”). This can electrocute utility workers and violates NEC codes .

Post-Use Maintenance

- Cool Down: Let generators run unloaded for 5 minutes to stabilize internals.

- Disconnect: Remove parallel cables before shutting down.

- Storage Prep:

- Drain fuel or add stabilizer.

- Clean air filters; check spark plugs.

- Cable Inspection: Look for fraying or corrosion—replace damaged cables immediately.

Legal & Code Compliance

- NEC Requirements: Transfer switches are mandatory for home connections (NEC 700.5) .

- Utility Notifications: Some regions require permits for generator-grid interfaces .

- Inspection: Systems feeding home panels often need an electrician’s certification.

Troubleshooting & FAQs

Table: Common Parallel Generator Issues

| Problem | Likely Cause | Solution |

|---|---|---|

| One generator shuts down | Overload or fuel starvation | Reduce load; check fuel filter |

| No power at outlets | Loose cable; tripped breaker | Re-seat connections; reset breaker |

| Unstable voltage | Poor synchronization | Re-sync using a voltmeter |

| Excessive vibration | Engine speed mismatch | Adjust governor on lagging unit |

FAQs

- Q: Can I parallel an inverter with a conventional generator?

A: No—waveform differences will damage electronics . - Q: Why does my parallel setup only deliver 3,000W from two 2,000W units?

A: Mismatched sizes or poor synchronization caps output at the weaker unit’s capacity . - Q: Do paralleled generators share fuel equally?

A: No—the unit under heavier load consumes more fuel. Balance loads for efficiency .

Conclusion: Power Responsibly

Paralleling generators unlocks unparalleled flexibility—doubling power while preserving portability and redundancy. However, success hinges on compatibility, precise synchronization, and safety-first practices. Always:

- Use identical inverter generators with manufacturer kits.

- Ground units and install transfer switches for home use.

- Monitor loads to prevent overloading one unit.

For complex setups (e.g., solar-generator hybrids), consult certified electricians or manufacturers like Cummins or Solis . By mastering these principles, you’ll harness scalable power safely—whether for a remote cabin or a critical hospital backup system.

✨ Pro Tip: Practice synchronization with low-wattage devices (e.g., lamps) before high-stakes scenarios.