Generator Maintenance Checklist

As a generator owner, I know how important regular maintenance is for optimal performance and longevity.

In this article, I’ll provide a comprehensive generator maintenance checklist.

From daily checks on oil, coolant, and fuel levels, to weekly inspections of pressure and voltage, and monthly tasks like cleaning spark plugs, you’ll find everything you need to keep your generator in top shape.

I’ll also offer tips on safety, choosing the right fuel, and the quietest generators on the market.

Stay tuned for reliable backup power!

Key Takeaways

- Daily generator maintenance checklist includes checking oil level, coolant level, fuel level, battery charge level, exhaust temperature, and air filter.

- Weekly generator maintenance checklist includes checking oil pressure, coolant pressure, voltage and amperage output, control panel and instrumentation, and belts and hoses for wear and tension.

- Monthly generator maintenance checklist includes checking and cleaning spark plugs, alternator and starter motor, electrical connections and wiring, exhaust system for leaks, and performing load bank test if required.

- Yearly generator maintenance checklist includes changing oil and oil filter, air filter, fuel filter, coolant, checking and adjusting valve clearance, performing load bank test if required, and checking generator under load.

Daily Generator Maintenance Checklist

In my daily generator maintenance checklist, I start by checking the oil level. This is one of the most important generator maintenance tips. Regularly checking the oil level ensures that the generator is properly lubricated and running smoothly. It’s crucial to maintain the correct oil level to prevent damage to the engine and ensure the generator’s longevity.

Additionally, regular generator maintenance is of utmost importance. It helps to identify any potential issues before they become major problems. By following a comprehensive maintenance checklist, you can keep your generator in optimal condition and prevent unexpected breakdowns.

Remember to consult the generator manual and manufacturer instructions for specific maintenance guidelines. Keeping records of your maintenance activities will also help track the generator’s performance over time.

Weekly Generator Maintenance Checklist

I check the oil pressure and coolant pressure on a weekly basis to ensure the optimal functioning of my generator. It’s important to regularly inspect and maintain the generator to avoid any issues.

Here is my weekly generator maintenance checklist:

- Checking spark plugs: Regularly inspect the spark plugs for proper functioning. Fouled or damaged spark plugs can cause starting issues and poor performance.

- Checking proper belt tension: Ensure that the belts are properly tensioned. Loose belts can result in inefficient power transmission and potential damage to the generator.

- Checking voltage and amperage output: Verify the voltage and amperage output to ensure that the generator is supplying the required power.

- Checking control panel and instrumentation: Inspect the control panel and instrumentation for any signs of damage or malfunction.

- Checking belts and hoses for wear and proper tension: Examine the belts and hoses for signs of wear and ensure they’re properly tensioned.

Monthly Generator Maintenance Checklist

I typically perform the monthly generator maintenance checklist to ensure that my generator is in optimal condition. Following a generator maintenance schedule is crucial for the proper functioning and longevity of the equipment.

Monthly maintenance plays a vital role in detecting and addressing any potential issues before they escalate. It allows me to check and clean spark plugs, inspect the alternator and starter motor, and ensure that all electrical connections and wiring are secure. Additionally, I examine the exhaust system for leaks and perform a load bank test if necessary.

Yearly Generator Maintenance Checklist

The yearly generator maintenance checklist includes:

- Changing the oil and oil filter

- Replacing the air filter

- Changing the fuel filter

- Changing the coolant

- Checking and adjusting valve clearance

- Performing a load bank test if required.

This generator maintenance schedule is crucial for the optimal performance and longevity of your generator. Neglecting yearly maintenance can lead to costly repairs and even generator failure.

By following the checklist, you ensure that your generator is in top-notch condition and ready to provide reliable backup power when you need it most.

Regular maintenance not only extends the lifespan of your generator but also helps identify any potential issues before they become major problems.

Don’t underestimate the importance of yearly maintenance to keep your generator running smoothly.

Generator Safety and Dangers

When operating a generator, it’s important to be aware of the potential safety hazards and dangers. One of the major risks is carbon monoxide poisoning. Generators produce this odorless gas, which can be deadly if inhaled in high concentrations. It’s crucial to always operate generators in well-ventilated areas and never indoors or in enclosed spaces.

Another safety concern is fuel storage. Incorrect handling or storage of fuel can result in fire hazards. It’s important to store fuel in approved containers away from any potential ignition sources. Additionally, make sure to follow proper fuel storage guidelines and never overfill the fuel tank of the generator.

| Maintenance Interval | Tasks |

|---|---|

| Daily | – Check oil level |

| – Check coolant level | |

| – Check fuel level | |

| – Check battery charge level | |

| – Check exhaust temperature | |

| – Clean air filter (if applicable) | |

| Weekly | – Check oil pressure |

| – Check coolant pressure | |

| – Check spark plugs | |

| – Check belt tension | |

| – Check voltage and amperage output | |

| – Inspect control panel and instrumentation | |

| Monthly | – Check and clean spark plugs |

| – Inspect alternator and starter motor | |

| – Inspect electrical connections and wiring | |

| – Inspect exhaust system for leaks | |

| – Perform load bank test (if required) | |

| Yearly | – Change oil and oil filter |

| – Replace air filter | |

| – Change fuel filter | |

| – Change coolant | |

| – Check and adjust valve clearance | |

| – Perform load bank test (if required) |

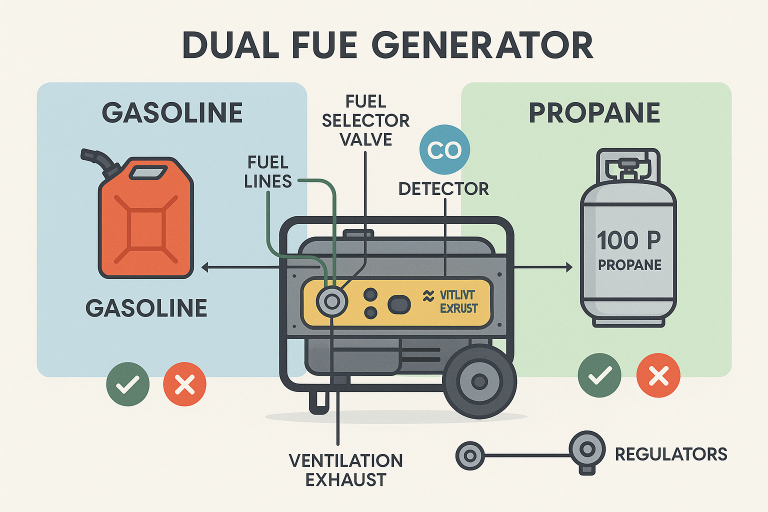

Choosing the Right Fuel for Portable Generators

One important consideration when choosing a fuel for portable generators is the type that best suits my needs in terms of performance and efficiency. Factors affecting fuel efficiency include the specific generator model, load size, and operating conditions.

Here are some pros and cons of different fuel types to help in the decision-making process:

Gasoline:

- Pros: Readily available, portable, and suitable for smaller generators.

- Cons: Shorter shelf life, can be volatile, and less efficient compared to other fuel types.

Diesel:

- Pros: Better efficiency, longer storage life, and widely available.

- Cons: Higher upfront cost, emits more pollutants, and requires regular maintenance.

Propane:

- Pros: Clean-burning, easy to store and transport, and longer shelf life.

- Cons: Limited availability in certain areas, lower energy density, and may require additional equipment.

Natural gas:

- Pros: Abundant and cost-effective fuel source, cleaner burning, and low emissions.

- Cons: Limited availability in remote areas, requires a dedicated pipeline or storage tank, and may have lower energy density.

Considering these factors and weighing the pros and cons, I can choose the fuel type that best suits my needs for optimal performance and efficiency.

Quietest Generators

I prefer generators that operate below 60 decibels as they’re the quietest option available. Generator noise reduction is achieved through the use of advanced technology and innovative designs. These quiet generators are perfect for various applications such as camping, outdoor events, and residential areas.

One popular type of generator known for its quiet operation is the inverter generator. Inverter generators are designed to deliver stable and clean power, while also minimizing noise levels. They’re highly efficient and produce less noise compared to traditional generators.

Many manufacturers offer quiet generator models that prioritize noise reduction without compromising performance. Investing in a quiet generator ensures a peaceful and enjoyable experience while still providing reliable power backup.

Conclusion

In conclusion, regular maintenance is crucial for ensuring optimal performance and longevity of your generator. By following the comprehensive checklist provided, you can keep your generator in top shape and minimize risks associated with its operation.

Additionally, choosing the right fuel for portable generators and understanding generator safety measures will further enhance its reliability.

With proper maintenance and safety precautions, your generator will be ready to provide reliable backup power whenever you need it most.