Generac Generator Problems: Common Complaints and Solutions

Generac is a household name when it comes to backup power solutions, trusted by homeowners, businesses, and industries alike. With a diverse range of generators designed for residential, commercial, and industrial applications, Generac offers reliable performance and innovation. However, like any mechanical device, Generac generators are not immune to occasional issues. Whether you’re dealing with a failure to start, voltage irregularities, or controller malfunctions, understanding these common problems and their solutions can save you time, money, and frustration.

This comprehensive guide delves into the most frequently reported complaints from Generac generator owners. It provides detailed troubleshooting steps, preventive maintenance tips, and insights into warranty concerns and customer service experiences. Additionally, we’ll outline when it’s best to call a professional for assistance.

Recommended Products for Generac Generator Maintenance and Repairs

| Product | Description | Amazon Link |

|---|---|---|

| Generac Maintenance Kit | All-in-one service kit for routine maintenance of Generac generators | View on Amazon |

| Briggs & Stratton Generator Cover | Weather-resistant cover to protect generators when not in use | View on Amazon |

| Generator Wheel Kit | Mobility kit for moving portable generators easily | View on Amazon |

Section 1: Common Generac Generator Problems & Solutions

1. Failure to Start

Complaint: The generator won’t crank, or it cranks but fails to start.

Possible Causes & Fixes:

- Dead or Weak Battery: The battery is often the culprit. Check the voltage (it should read around 12.6V). Clean corroded terminals and replace the battery if necessary.

- Fuel Issues: Ensure the fuel tank isn’t empty. Inspect fuel lines for blockages, replace filters, and drain stale gasoline, especially in portable models.

- Choke Malfunction (Air-Cooled Models): Examine the choke linkage and solenoid for proper operation.

- Faulty Safety Switches: Low oil or coolant sensors may prevent startup. Verify fluid levels and reset the switches if needed.

2. Exercise Cycle Problems

Complaint: The generator skips self-tests or operates erratically during its weekly exercise cycle.

Possible Causes & Fixes:

- Incorrect Settings: Double-check the exercise schedule programmed into the controller.

- Weak Battery: A failing battery may lack the charge to complete the cycle. Test and replace it if necessary.

- Controller Glitch: Reset the system or update the firmware through an authorized dealer.

3. Overcranking (Error Code 1100)

Complaint: The generator cranks excessively before shutting down with an “Overcrank” alert.

Possible Causes & Fixes:

- Fuel Delivery Problems: Inspect the fuel supply, valves, and filters. Low gas pressure could also trigger this error.

- Ignition System Failure: Test spark plugs, coils, and wiring for faults.

- Air Intake Blockage: A clogged air filter restricts airflow. Clean or replace the filter as needed.

4. Controller Errors & Malfunctions

Complaint: Blank screens, frozen displays, or nonsensical error codes.

Possible Causes & Fixes:

- Loose Wiring: Check all battery terminals and controller connections for tightness.

- Software Glitch: Perform a system reset or update the firmware via a certified technician.

- Faulty Controller: If the issue persists, the controller may need professional replacement.

5. Voltage Output Problems (High/Low/Unstable)

Complaint: Lights flicker, electronics behave erratically, or voltage readings are inconsistent.

Possible Causes & Fixes:

- Overloading: Reduce connected loads to alleviate strain on the generator.

- Faulty Voltage Regulator (AVR): This component often causes instability. Professional testing is recommended.

- Speed (Hz) Fluctuations: Governor control issues may be at play. Inspect the stepper motor or linkages for wear.

6. Excessive Noise or Vibration

Complaint: Unusual rattling, grinding, or loud operation.

Possible Causes & Fixes:

- Loose Mounting Bolts: Tighten all hardware securing the generator base.

- Damaged Muffler/Exhaust: Inspect for cracks or loose components and repair as needed.

- Worn Motor Mounts: Replace deteriorated mounts to restore smooth operation.

7. Rapid Oil Consumption or Leaks

Complaint: The generator burns oil too quickly or exhibits visible leaks.

Possible Causes & Fixes:

- External Leaks: Check gaskets, the oil pan, and the drain plug for signs of leakage.

- Internal Engine Wear: Worn piston rings or valve seals may require professional intervention.

8. Overheating (Error Code 1400)

Complaint: The generator shuts down due to high temperatures.

Possible Causes & Fixes:

- Blocked Airflow: Clear debris from cooling vents to ensure proper ventilation.

- Low Coolant (Liquid-Cooled Models): Top up the coolant reservoir if levels are low.

- Faulty Temperature Sensor: Test the sensor and replace it if defective.

| Problem | Possible Causes | Solutions |

|---|---|---|

| Failure to Start | – Dead or weak battery – Empty fuel tank or blocked fuel lines – Choke malfunction – Faulty safety switches (low oil/coolant sensors) | – Check battery voltage (~12.6V), clean terminals, or replace. – Refill fuel, check lines, replace filters. – Inspect choke linkage/solenoid. – Verify fluid levels and reset switches. |

| Exercise Cycle Problems | – Incorrect controller settings – Weak battery – Controller glitch | – Verify exercise schedule in controller. – Test and replace battery if needed. – Reset system or update firmware via dealer. |

| Overcranking (Error Code 1100) | – Fuel delivery issues (low pressure, blockages) – Ignition system failure – Air intake blockage | – Check fuel supply, valves, and filters. – Test spark plugs, coils, and wiring. – Clean or replace air filter. |

| Controller Errors | – Loose wiring – Software glitch – Faulty controller | – Tighten battery terminals and connections. – Reset system or update firmware. – Replace controller professionally. |

| Voltage Output Problems | – Overloading – Faulty voltage regulator (AVR) – Governor control issues | – Reduce connected loads. – Test and replace AVR. – Inspect stepper motor or linkages. |

| Excessive Noise/Vibration | – Loose mounting bolts – Damaged muffler/exhaust – Worn motor mounts | – Tighten hardware. – Repair or replace damaged components. – Replace worn mounts. |

| Oil Consumption/Leaks | – External leaks (gaskets, oil pan) – Internal engine wear (piston rings, seals) | – Inspect and repair external leaks. – Seek professional repair for internal engine issues. |

| Overheating (Error Code 1400) | – Blocked airflow – Low coolant (liquid-cooled models) – Faulty temperature sensor | – Clear debris from vents. – Top up coolant. – Test and replace temperature sensor. |

Section 2: Warranty & Customer Service Concerns

Many users express frustration with Generac’s warranty process:

- Denied Claims: Some claims are rejected due to issues deemed “installer error.”

- Hidden Costs: Maintenance contracts (~$395/year) and diagnostic fees can add up quickly.

- Slow Response Times: Complaints highlight delays in repairs and unresponsive customer support.

Tip: Always document routine maintenance and retain receipts to strengthen your case for warranty claims.

| Issue | Details | Recommendations |

|---|---|---|

| Denied Claims | Some warranty claims are rejected due to “installer error.” | Document all maintenance activities and retain receipts for warranty claims. |

| Hidden Costs | Maintenance contracts (~$395/year) and diagnostic fees can add up. | Budget for annual maintenance or negotiate service agreements upfront. |

| Slow Response Times | Complaints about delays in repairs and unresponsive customer support. | Use certified dealers; escalate unresolved issues to Generac HQ. |

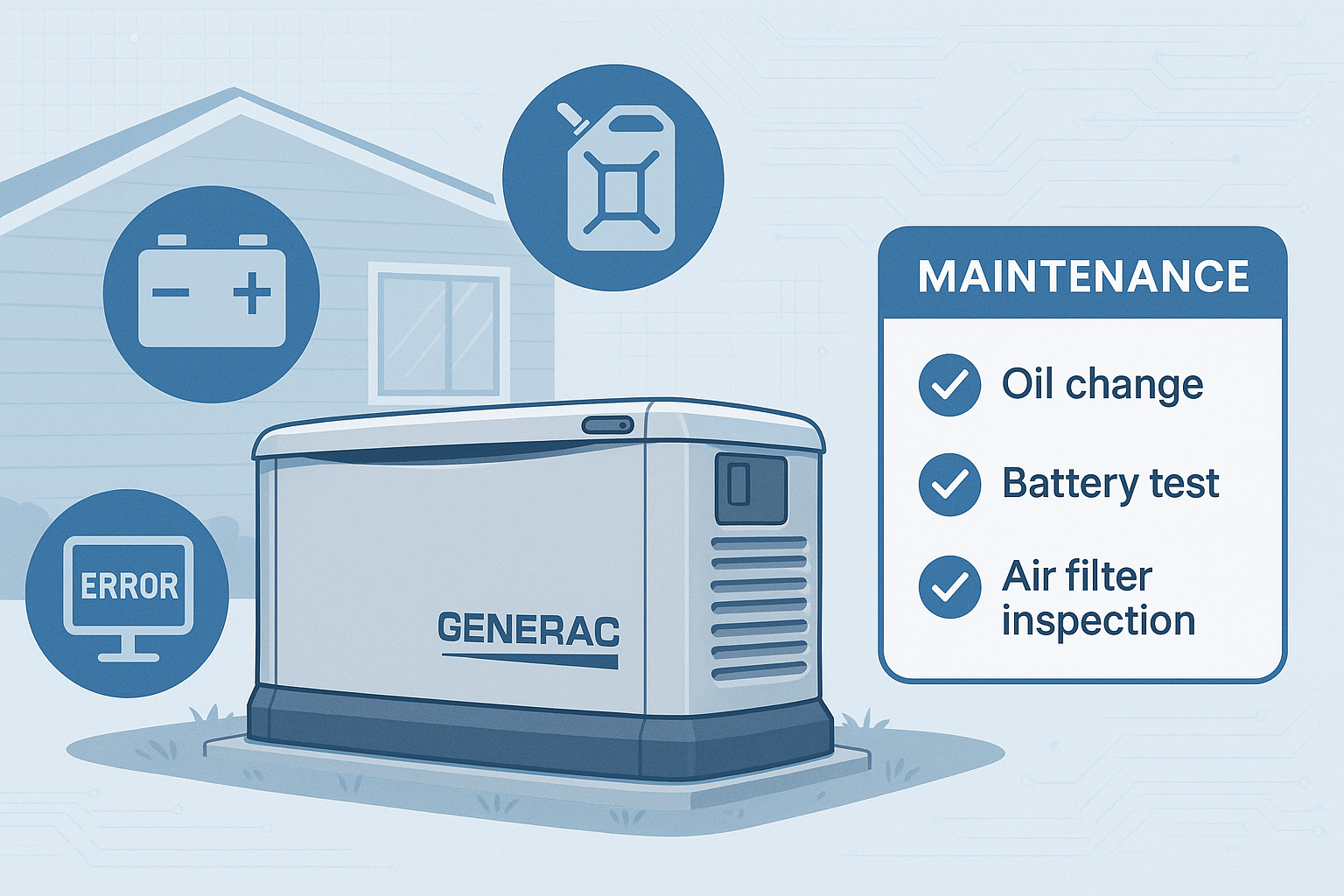

Section 3: Preventative Maintenance Tips

To minimize the risk of common problems:

- Regular Oil Changes: Follow the manufacturer’s schedule (every 100 hours or annually).

- Battery Care: Test the battery voltage bi-annually and replace it every 2-3 years.

- Fuel Management: Use fuel stabilizers for gasoline models and ensure propane tanks remain full.

- Exercise Cycle: Confirm that weekly self-tests run smoothly without interruptions.

| Task | Frequency | Steps |

|---|---|---|

| Oil Changes | Every 100 hours or annually | Follow manual schedule; use recommended oil type and grade. |

| Battery Care | Bi-annually | Test voltage (~12.6V); clean terminals; replace every 2–3 years. |

| Fuel Management | Before storage or long idle periods | Use fuel stabilizers for gasoline; ensure propane tanks are full. |

| Exercise Cycle Verification | Weekly | Ensure weekly self-tests run uninterrupted; fix any errors promptly. |

| Air Filter Inspection | Annually or as needed | Check for clogs; clean or replace filters regularly. |

| Cooling System Check | Annually | Clear debris from vents; top up coolant in liquid-cooled units. |

Section 4: When to Call a Professional

While many issues can be resolved through DIY troubleshooting, some scenarios require expert assistance:

- Complex Electrical Issues: Problems involving the AVR or controller faults.

- Internal Engine Repairs: Compression loss or major oil leaks.

- Persistent Error Codes: If troubleshooting doesn’t resolve recurring error codes.

| Scenario | Reason | Action |

|---|---|---|

| Complex Electrical Issues | AVR/controller faults | Contact certified technician for diagnostics and repair. |

| Internal Engine Repairs | Compression loss, oil leaks | Seek professional assistance for internal engine service. |

| Persistent Error Codes | Recurring issues after DIY fixes | Consult a dealer or technician for deeper diagnostics. |

Conclusion

Generac generators are renowned for their reliability, but they are not immune to occasional hiccups. By familiarizing yourself with common issues—such as battery failures, fuel delivery problems, and controller errors—you can troubleshoot effectively and avoid costly repairs. Regular maintenance is essential for maximizing the lifespan of your generator, while knowing when to seek professional help can prevent further damage.

For severe issues, such as recalls related to portable models with defective handles, prioritize safety and contact Generac or a certified dealer immediately. With proper care and attention, your Generac generator will continue to provide dependable backup power for years to come.

Final Note: Always refer to your owner’s manual for specific guidance tailored to your model. For persistent or complex problems, don’t hesitate to consult a certified technician.